Category : Turbocharger Testing

Back to Blog

Share This

FMIC FITTMENTS

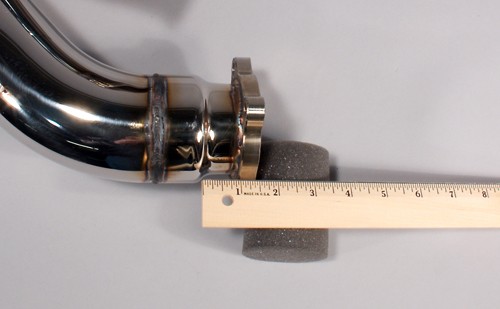

Originally we made our kit somewhat universal to other FMICs. While the connection from the turbo to the FMIC can be made, it was a little tricky to get just right. With our current kits we are shipping we simplified this quite a bit with a single Silicone hose that goes from the turbo to the FMIC connection. This Jog eliminates extra couplers, and pipes that caused some issues.

TURBO AND HOUSINGS

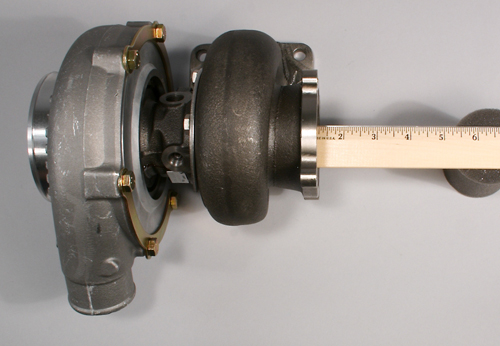

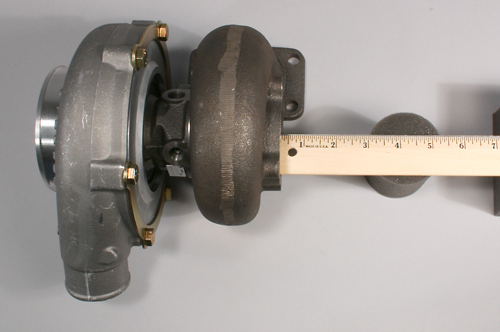

Lets go over a couple things with the housings. Like I have said many times before, and have shown many times before, there is no difference in the housings. We choose to use the housing we did (a long time ago), as this housing was much more compact, and was readily available from our turbo supplier. These are the T31 exhaust housings people are referring to. These housings are a T3 inlet and have a short 2.5€ outlet. The newer Garrett GT housing has the same T3 inlet but a longer 3€ outlet. With out saying anymore, people jump to the conclusion that the 3€ is better as it is bigger, because in a turbo exhaust system bigger IS better. You have to look at both housings and understand what makes them different, not better. First off the turbine wheel inducer for all these turbos are smaller than 2.5€, which means that in order for it to get to 3€, some flaring is done. Its in this flaring where things vary from the T31 to the Gt housing. The T31 housing basically has no flare (inserter Office Space joke here). The end of the turbine wheel is very close to the flange where the DP bolts to. Our DP bolts to this and starts at 2.5€ then quickly is flared to 3€. The GT housing is very long so it goes from the turbine wheel to the 3€ oulet in a couple of inches. Basically accomplishing the 3€ OD in the same distance as our kit with the 2.5€ outlet. Since we have a Garrett Engineer assigned to us of course I proposed the question whats the difference, his exact response below. €œWe have never run a test between the two housings for that exact turbine wheel. (I asked hims specifically on the GT3582R ) We did do a test a different turbine wheel and the performance for the 2.5" housing was slightly less (on the order of the uncertainty of the measurement). I would suspect you would observe no performance difference.€ Add to that are some pictures showing the differences:

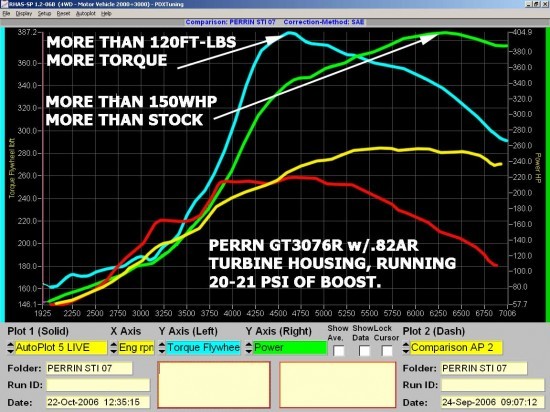

Proof is in the pudding!!!!!! (Not sure where that came from but I am sure Wikipedia has something on it) There are a couple of naysayers out there about this housing, but they are not comparing apples to apples. If this housing was so bad, then we would see some HP or spool differences in cars with GT housings, but this is just not the case. We have cars with Gt3076R w/.82 turbos and they spool around 4000, and make about 400WHP on pump gas, and 460 on race gas. This is the same thing seen on the GT housings, and in fact a somewhat local customer had one our kits modded for the GT housing, and his car spooled just like others, and made about the same HP as others. If this T31 exhaust housing was a choke, or a hindrance to the WRX€™s making power, I think there would be a lot more people complaining about how their car doesn€™t make enough power.

Proof is in the pudding!!!!!! (Not sure where that came from but I am sure Wikipedia has something on it) There are a couple of naysayers out there about this housing, but they are not comparing apples to apples. If this housing was so bad, then we would see some HP or spool differences in cars with GT housings, but this is just not the case. We have cars with Gt3076R w/.82 turbos and they spool around 4000, and make about 400WHP on pump gas, and 460 on race gas. This is the same thing seen on the GT housings, and in fact a somewhat local customer had one our kits modded for the GT housing, and his car spooled just like others, and made about the same HP as others. If this T31 exhaust housing was a choke, or a hindrance to the WRX€™s making power, I think there would be a lot more people complaining about how their car doesn€™t make enough power.

Regarding the support brace. This is a part we have developed a year or 2 after we release our kits. The brace is a very simple and effective brace that limits the €œpossibly€ damaging left and right vibrations. We say possibly as there are many turbo kits out there with no brace and have no issues. Because of the way the kit bolts to the car, it is somewhat braced in its self. This is why so far, there is no need for one.

We currently have braces in stock for the old GT35R, but since our kit is changing, we will not have braces for the other turbos for a while.

That should clear up peoples concerns about the kits performance and fitment issues.

Regarding the support brace. This is a part we have developed a year or 2 after we release our kits. The brace is a very simple and effective brace that limits the €œpossibly€ damaging left and right vibrations. We say possibly as there are many turbo kits out there with no brace and have no issues. Because of the way the kit bolts to the car, it is somewhat braced in its self. This is why so far, there is no need for one.

We currently have braces in stock for the old GT35R, but since our kit is changing, we will not have braces for the other turbos for a while.

That should clear up peoples concerns about the kits performance and fitment issues.

The Changes!

Now onto the changes we have and are making. We are switching to the GT housing!! Since there are those who €œThink€ the T31 is not as good as the GT housing, what better way to satisfy everyone than to change to the GT housing! While we feel there is ZERO benefit in HP or spool, the other benefits are supply issues. Since the inception of our turbo kit, we have gone direct with Garrett, and getting the newer housings is much easier, as they are an off the shelf part. So switching housings forces a few things like DP and uppipe changes, which we have added more room around the WG, and clearance around the chassis. While our kit will hang a little lower, it will eliminate any issues with clearance with different motor mounts or slight variation in cars.

Blow thru boost tube

This is a part we have been selling for a while now, but it is change to the new kit because you HAVE to have it (or a stand alone ECU). We have found that this part makes tuning simpler, eliminates issues with stop and go traffic (making the MAF see high temps), nearly eliminates rich or lean conditions with leaks in boost tubes, or intake hose.Intake system.

This is an item that was made for this future kit, as well as the old kit. No more silicone! Well at least big pieces of silicone. The new intake system is now a cold air tube that fits down in the fender well. While this part is a little trickier to install, it really cleans up the engine bay. I like guys at Crawford performance, and in no way do we say they make a bad part. Both of us have great parts that fit people€™s needs. Their kit requires their FMIC, ours fits with our FMIC and other OEM turbo fitment types.

I like guys at Crawford performance, and in no way do we say they make a bad part. Both of us have great parts that fit people€™s needs. Their kit requires their FMIC, ours fits with our FMIC and other OEM turbo fitment types.