Category : Dyno Test & Tune

Back to Blog

Share This

The PERRIN turbo inlet hose has been one of our best selling, long standing products for many years. Since the beginning, we have made our part different than the rest in that we didn't just make a copy of the OEM part. We had something different in mind to make the installation of this go much easier, and also out perform other turbo inlet hoses offered by our competition.

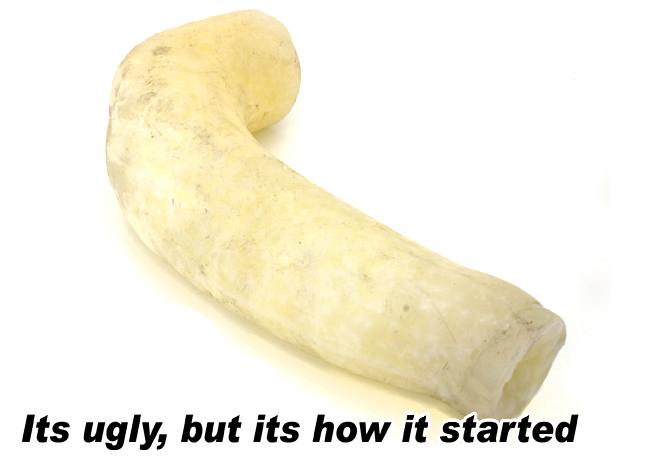

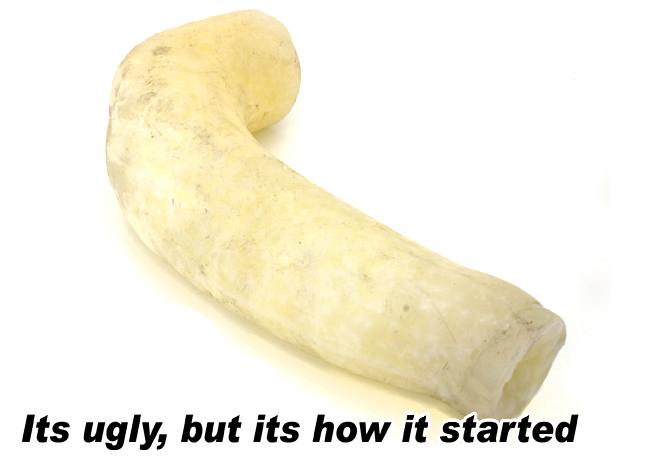

We looked at many different ways to build it. The criteria was that it had to be easy to install and inexpensive enough so the value equaled the HP gained. Sounds easy! I spent a lot of time trying to make some from carbon fiber. This entailed a pattern of the inlet hose, and a mold of the pattern. A wax casting was made from the mold and a carbon "sock" was pulled over it. When cured, we just heated it up and out came the wax. This didn't work so well and was super messy.

Before the mold was thrown away, we tried one last thing. A carbon fiber "sock" was pulled over a specially made bladder, and inserted into the mold. With resin soaked into the carbon, and the bladder pressured up the mold, out comes a carbon inlet hose! Sounds complicated, but this is how a lot of these kinds of things are made. However, for a smaller company like us, it was messy and time consuming.

We looked at many different ways to build it. The criteria was that it had to be easy to install and inexpensive enough so the value equaled the HP gained. Sounds easy! I spent a lot of time trying to make some from carbon fiber. This entailed a pattern of the inlet hose, and a mold of the pattern. A wax casting was made from the mold and a carbon "sock" was pulled over it. When cured, we just heated it up and out came the wax. This didn't work so well and was super messy.

Before the mold was thrown away, we tried one last thing. A carbon fiber "sock" was pulled over a specially made bladder, and inserted into the mold. With resin soaked into the carbon, and the bladder pressured up the mold, out comes a carbon inlet hose! Sounds complicated, but this is how a lot of these kinds of things are made. However, for a smaller company like us, it was messy and time consuming.

So the next best thing was silicone. Silicone is flexible and this would be great for installation. After a little engineering and after NOT looking at the stock part, we created our first prototype tool. Looking at this from an installers point of view, we came up with the idea to move the spigots around to make the part installable while keeping the manifold bolted down. This simple idea not only eliminated the need of the intake manifold coming off, but it eliminated cost in installation fees.

So the next best thing was silicone. Silicone is flexible and this would be great for installation. After a little engineering and after NOT looking at the stock part, we created our first prototype tool. Looking at this from an installers point of view, we came up with the idea to move the spigots around to make the part installable while keeping the manifold bolted down. This simple idea not only eliminated the need of the intake manifold coming off, but it eliminated cost in installation fees.

This polished Stainless Steel tool created the hose you see below. Silicone is wrapped around the tool, then mylar is wrapped over this to keep the silicone tight to the tool. It is then baked in an oven to cure and then the hose is removed from the tool. The process for doing this is very labor intensive, but it creates a hose that is very durable, easy to install, and very heat resistant. The first version of this hose was made in 4-ply's (silicone and polyester). Later on we changed it to 5 ply's and a longer cure time to stiffen up the hose a bit.

This polished Stainless Steel tool created the hose you see below. Silicone is wrapped around the tool, then mylar is wrapped over this to keep the silicone tight to the tool. It is then baked in an oven to cure and then the hose is removed from the tool. The process for doing this is very labor intensive, but it creates a hose that is very durable, easy to install, and very heat resistant. The first version of this hose was made in 4-ply's (silicone and polyester). Later on we changed it to 5 ply's and a longer cure time to stiffen up the hose a bit.

Over the years, competitors have come into the market with similar parts, and taken some of the market share. This has driven us to look at new methods of building the hose, as well as making it even better. We could make it from an aluminum tube, but someone already does this. We looked at a cast aluminum part, but it would more expensive than the silicone. Every method we looked back to all had the same problem, installation time and cost. Instead of reinventing the part, we decided to build upon our silicone design and make it even better.

Over the years, competitors have come into the market with similar parts, and taken some of the market share. This has driven us to look at new methods of building the hose, as well as making it even better. We could make it from an aluminum tube, but someone already does this. We looked at a cast aluminum part, but it would more expensive than the silicone. Every method we looked back to all had the same problem, installation time and cost. Instead of reinventing the part, we decided to build upon our silicone design and make it even better.

Again, this small issue could be completely remedied if we made a simple and effective change. We could add a wire that would run through the middle of the hose and would provide enough support that collapsing issues would be gone completely and still be able to install it! So there we have it! Along with the added wire, we moved the spigots around, increased the spigot sizes, added some additional connectors, and added slight revisions to the instructions. We feel that these changes will make an already great part even better and with ZERO change in price.

Again, this small issue could be completely remedied if we made a simple and effective change. We could add a wire that would run through the middle of the hose and would provide enough support that collapsing issues would be gone completely and still be able to install it! So there we have it! Along with the added wire, we moved the spigots around, increased the spigot sizes, added some additional connectors, and added slight revisions to the instructions. We feel that these changes will make an already great part even better and with ZERO change in price.

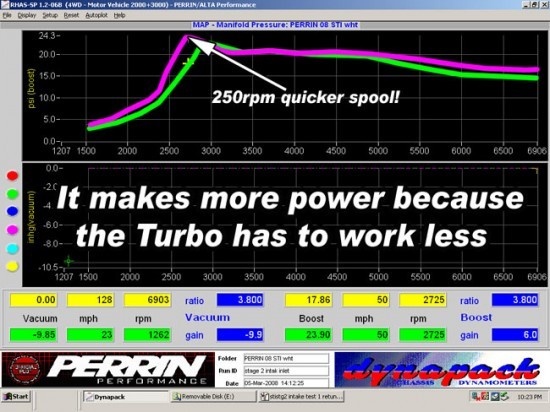

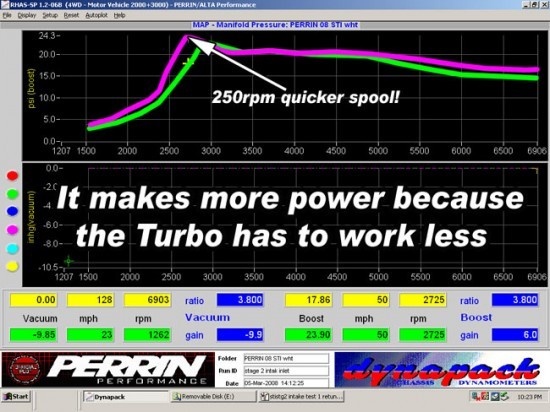

There are 2 very important parts of the RPM band to look at. The green line represents the boost on our car (Stage 2 STI) with the stock turbo inlet, and the purple line shows the same car with a PERRIN inlet hose installed. These runs were done roughly 40minutes apart, removing any major variables to HP and TQ. As you can clearly see, the OEM inlet hose is a restriction as the turbo builds boost faster and holds more at higher RPM.

There are 2 very important parts of the RPM band to look at. The green line represents the boost on our car (Stage 2 STI) with the stock turbo inlet, and the purple line shows the same car with a PERRIN inlet hose installed. These runs were done roughly 40minutes apart, removing any major variables to HP and TQ. As you can clearly see, the OEM inlet hose is a restriction as the turbo builds boost faster and holds more at higher RPM.

The power graphs show the turbo spooling up quicker and netting more low end torque and power. At the same time, the slight increase in boost at the upper RPM provides more HP from 5500 RPM. An ECU retuned specifically for the inlet hose could net a few more HP as the turbo runs more efficiently. But for the above test, we are running our Stage 2 mapping that was designed for the Intake system. This is showing the real world HP that other customer should expect to see.

The power graphs show the turbo spooling up quicker and netting more low end torque and power. At the same time, the slight increase in boost at the upper RPM provides more HP from 5500 RPM. An ECU retuned specifically for the inlet hose could net a few more HP as the turbo runs more efficiently. But for the above test, we are running our Stage 2 mapping that was designed for the Intake system. This is showing the real world HP that other customer should expect to see.

HISTORY LESSON

When we got the WRX and started making parts for it, we looked to Japan for some of our inspiration, as they had the car for much longer. One of the more common parts we saw people replacing was their OEM inlet hoses. Before we had decided to make one, we had been installing these on customer cars for a couple years and come to hate the installation. This was due to the removal of the intake manifold, which meant about a 3 hour install job. This seemed ridiculous as the customer would buy a $300 part, then pay $200-300 to have it installed. All this for about 10HP? This is what sparked us to make the PERRIN inlet hose. We wanted to make the installation quicker and the part less expensive so customers would pay more like $300 installed. We looked at many different ways to build it. The criteria was that it had to be easy to install and inexpensive enough so the value equaled the HP gained. Sounds easy! I spent a lot of time trying to make some from carbon fiber. This entailed a pattern of the inlet hose, and a mold of the pattern. A wax casting was made from the mold and a carbon "sock" was pulled over it. When cured, we just heated it up and out came the wax. This didn't work so well and was super messy.

Before the mold was thrown away, we tried one last thing. A carbon fiber "sock" was pulled over a specially made bladder, and inserted into the mold. With resin soaked into the carbon, and the bladder pressured up the mold, out comes a carbon inlet hose! Sounds complicated, but this is how a lot of these kinds of things are made. However, for a smaller company like us, it was messy and time consuming.

We looked at many different ways to build it. The criteria was that it had to be easy to install and inexpensive enough so the value equaled the HP gained. Sounds easy! I spent a lot of time trying to make some from carbon fiber. This entailed a pattern of the inlet hose, and a mold of the pattern. A wax casting was made from the mold and a carbon "sock" was pulled over it. When cured, we just heated it up and out came the wax. This didn't work so well and was super messy.

Before the mold was thrown away, we tried one last thing. A carbon fiber "sock" was pulled over a specially made bladder, and inserted into the mold. With resin soaked into the carbon, and the bladder pressured up the mold, out comes a carbon inlet hose! Sounds complicated, but this is how a lot of these kinds of things are made. However, for a smaller company like us, it was messy and time consuming.

So the next best thing was silicone. Silicone is flexible and this would be great for installation. After a little engineering and after NOT looking at the stock part, we created our first prototype tool. Looking at this from an installers point of view, we came up with the idea to move the spigots around to make the part installable while keeping the manifold bolted down. This simple idea not only eliminated the need of the intake manifold coming off, but it eliminated cost in installation fees.

So the next best thing was silicone. Silicone is flexible and this would be great for installation. After a little engineering and after NOT looking at the stock part, we created our first prototype tool. Looking at this from an installers point of view, we came up with the idea to move the spigots around to make the part installable while keeping the manifold bolted down. This simple idea not only eliminated the need of the intake manifold coming off, but it eliminated cost in installation fees.

This polished Stainless Steel tool created the hose you see below. Silicone is wrapped around the tool, then mylar is wrapped over this to keep the silicone tight to the tool. It is then baked in an oven to cure and then the hose is removed from the tool. The process for doing this is very labor intensive, but it creates a hose that is very durable, easy to install, and very heat resistant. The first version of this hose was made in 4-ply's (silicone and polyester). Later on we changed it to 5 ply's and a longer cure time to stiffen up the hose a bit.

This polished Stainless Steel tool created the hose you see below. Silicone is wrapped around the tool, then mylar is wrapped over this to keep the silicone tight to the tool. It is then baked in an oven to cure and then the hose is removed from the tool. The process for doing this is very labor intensive, but it creates a hose that is very durable, easy to install, and very heat resistant. The first version of this hose was made in 4-ply's (silicone and polyester). Later on we changed it to 5 ply's and a longer cure time to stiffen up the hose a bit.

Over the years, competitors have come into the market with similar parts, and taken some of the market share. This has driven us to look at new methods of building the hose, as well as making it even better. We could make it from an aluminum tube, but someone already does this. We looked at a cast aluminum part, but it would more expensive than the silicone. Every method we looked back to all had the same problem, installation time and cost. Instead of reinventing the part, we decided to build upon our silicone design and make it even better.

Over the years, competitors have come into the market with similar parts, and taken some of the market share. This has driven us to look at new methods of building the hose, as well as making it even better. We could make it from an aluminum tube, but someone already does this. We looked at a cast aluminum part, but it would more expensive than the silicone. Every method we looked back to all had the same problem, installation time and cost. Instead of reinventing the part, we decided to build upon our silicone design and make it even better.

CURRENT GENERATION TURBO INLET

So how can we make the part better? A very small but damaging issue we had with some of our parts, was the reports of them collapsing. To this day roughly ten out of thousands of parts were returned to us with this issue. The issue was due to the silicone not being cured long enough. While this was a very small issue to us, it was publicly exploited on the internet and made out to be a much bigger problem that it really was. Again, this small issue could be completely remedied if we made a simple and effective change. We could add a wire that would run through the middle of the hose and would provide enough support that collapsing issues would be gone completely and still be able to install it! So there we have it! Along with the added wire, we moved the spigots around, increased the spigot sizes, added some additional connectors, and added slight revisions to the instructions. We feel that these changes will make an already great part even better and with ZERO change in price.

Again, this small issue could be completely remedied if we made a simple and effective change. We could add a wire that would run through the middle of the hose and would provide enough support that collapsing issues would be gone completely and still be able to install it! So there we have it! Along with the added wire, we moved the spigots around, increased the spigot sizes, added some additional connectors, and added slight revisions to the instructions. We feel that these changes will make an already great part even better and with ZERO change in price.

DYNO PROVING

Again, we tried to one up our competition and prove that our part made HP versus just claiming it made HP. We had done tests in the past that were days or weeks apart and they always showed more boost and power but, they were not done close enough together to use this as proof. So we decided to do an install on the dyno on the same day to ensure that the testing was as legit as possible. When testing parts, sometimes we look how much power is gained by just bolting it on, and sometimes we look at how much HP is gained by bolting it on with an ECU retune. If we can show that a part makes power with just bolting it on, this normally means that even more can be had with a custom tune. In our testing we found that there are gains had without custom tuning, which is awesome as even more HP will be gained with further tuning of the ECU. There are 2 very important parts of the RPM band to look at. The green line represents the boost on our car (Stage 2 STI) with the stock turbo inlet, and the purple line shows the same car with a PERRIN inlet hose installed. These runs were done roughly 40minutes apart, removing any major variables to HP and TQ. As you can clearly see, the OEM inlet hose is a restriction as the turbo builds boost faster and holds more at higher RPM.

There are 2 very important parts of the RPM band to look at. The green line represents the boost on our car (Stage 2 STI) with the stock turbo inlet, and the purple line shows the same car with a PERRIN inlet hose installed. These runs were done roughly 40minutes apart, removing any major variables to HP and TQ. As you can clearly see, the OEM inlet hose is a restriction as the turbo builds boost faster and holds more at higher RPM.

The power graphs show the turbo spooling up quicker and netting more low end torque and power. At the same time, the slight increase in boost at the upper RPM provides more HP from 5500 RPM. An ECU retuned specifically for the inlet hose could net a few more HP as the turbo runs more efficiently. But for the above test, we are running our Stage 2 mapping that was designed for the Intake system. This is showing the real world HP that other customer should expect to see.

The power graphs show the turbo spooling up quicker and netting more low end torque and power. At the same time, the slight increase in boost at the upper RPM provides more HP from 5500 RPM. An ECU retuned specifically for the inlet hose could net a few more HP as the turbo runs more efficiently. But for the above test, we are running our Stage 2 mapping that was designed for the Intake system. This is showing the real world HP that other customer should expect to see.

BETTER THAN THE REST

We have the advantage over other brands. Our inlet hose is the only one on the market today that does NOT require the removal of the intake manifold! That is HUGE. Think about it, no fuel to drain, no water lines to remove, no gaskets to purchase, less nuts and bolts to deal with. A huge advantage if you do it yourself or pay a technician. Instead of paying for 4-6 hours labor and parts, you should only have to pay for 1-1.5 hours and no extra parts. To add to that, we are the only ones to prove our part makes power! When testing parts, we look at 2 different things, bolt on power, and ECU retune power. Because we can tune the ECU and make power, it is important to look at both methods to show real world gains and gains after a tune. For this part, we see great gains with no tuning, which means with an ECU retune there is even more to get! Below is a comparison of the PERRIN inlet hose compare to some of the aftermarket ones offered. There is not one single competitive brand mentioned below, its more of a conglomeration of all aftermarket parts.- PERRIN Inlet hose is made of high quality polyester reinforced 5 ply Silicone rated to -75F to 400F

- OEM is made of plastic and rubber which cracks over time

- PERRIN Inlet hose has a thick steel wire reinforcing hose from collapsing under extreme conditions

- Their Inlet hose has no steel wire keep hose from collapsing.

- PERRIN Inlet hose doesn't require removal of intake manifold making install time to be about an hour.

- Theirs requires intake manifold to be removed making install time 3-4 hours

- PERRIN Innovative design with larger inside diameter and relocated spigots

- Theirs, a copy of the OEM hose with little to no performance benefit.

- PERRIN proven HP done on dyno with back-to-back testing done in under an hour.

- Theirs, no dyno numbers, just claims of more airflow

- PERRIN Inlet hose Includes hardware and hoses with detailed instructions on how to install

- Theirs has nothing but a hose and expects you to "know" how to install it.

- PERRIN inlet hose includes hardware to make it compatible with other intakes and Front mount intercoolers

- Theirs not always compatible with FMIC's and aftermarket intake systems.