Category : Dyno Test & Tune

Back to Blog

Share This

Through out this article I will be referring to Water/methonal injection as WI. With this entire test and install, we are showcasing this as something anyone can do. There is not a single part of this test that a person should feel scared to do except for the tuning which should be left up to a professional tuner.

Water injection has been used in many industries for a very long time. We are finally bringing it to the Mini world! Many have seen our PWI-1 system, and if you read the features from our site, you will be sold on it compared to other systems. This article is not about the PWI-1 system, but about using WI on the Mini cooper.

Why would you want to use WI on the Mini? The Intercooler is small, and lacks in the cooling department, smaller SC pulleys increase the charge temps, all these things increase the engine tendency to detonate or knock. So since running race fuel every day is not practical, the next best thing is water/methonal injection! The WI is only on when you are above a certain load point. Meaning only when the engine is about a certain RPM and or boost level. So it only injects it when you need it. This makes the consumption rate very low for normal driving conditions.

WI is all about cooling, which in turn controls detonation which allows the engine to make more power, and more power safer. Normally just injecting the mixture nets a loss in power. But with some cars, because of limitations of fuel and how the ECU is tuned, they can gain power. With the Mini some have seen gains with just injecting water/methanol, but with this test we will have to see!

Using the wonderful BimCOM software from RossTech, we collected some great convincing data!

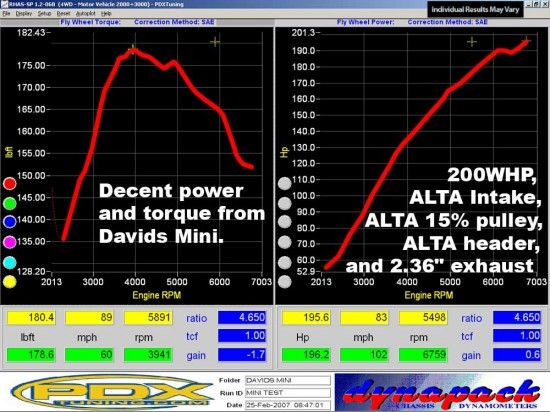

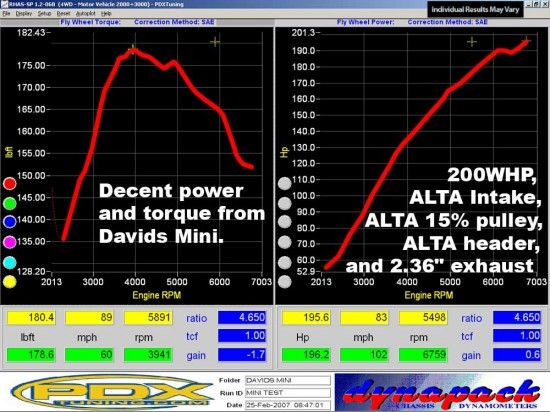

We started with a customers 2005 Mini Cooper S (which BTW, Mr. Sterns Mini is one of the sweetest Minis around). This car has an ALTA 15% SC pulley, ALTA header, ALTA intake, stock IC, and Invidia 60mm exhaust.

As with all Mini Cooper S€™s, or any boosted engine, more boost is the key to making power. Since boost isn€™t going to change much unless we increase the SC speed, by a smaller pulley, or higher redline, the increases are not going to be huge, or are they??

After drilling an tapping a 1/8NPT fitting into the bottom of the tank we are ready to re-install it back into the car. Next up is the primer pump install. This is a pretty simple job. Drilling a couple of holes to mount it, and connect the tank hose up to it and we are done. Wiring the pump is simple. The PWi-1 has 2 wires ready to go, so all we have to do is extend the wires to the pump.

After drilling an tapping a 1/8NPT fitting into the bottom of the tank we are ready to re-install it back into the car. Next up is the primer pump install. This is a pretty simple job. Drilling a couple of holes to mount it, and connect the tank hose up to it and we are done. Wiring the pump is simple. The PWi-1 has 2 wires ready to go, so all we have to do is extend the wires to the pump.

With the fender liner back in its time for the pump assembly and and wiring job. The pump assembly fits great in the window cowl area, and it is very easy to get a drill in there for the mounting holes. Besides the normal positive and negative connections, the only tricking connection is the fuel injector ground signal. This connection is important as this is how the PWI-1 picks up fuel injector duty cycle and determines how much water to inject.

With the fender liner back in its time for the pump assembly and and wiring job. The pump assembly fits great in the window cowl area, and it is very easy to get a drill in there for the mounting holes. Besides the normal positive and negative connections, the only tricking connection is the fuel injector ground signal. This connection is important as this is how the PWI-1 picks up fuel injector duty cycle and determines how much water to inject.

All done!

All done!

The last step in the installation is is the nozzle placement. Normally putting the nozzle before the IC is better, when the IC is in a bad place, or is very small. So the Mini should have the nozzle before the IC. The only problem with putting it before the IC is that there is no good place that will distribute the water over the charged air in the tube equally. Because of the wide opening, if we put the nozzle in the center, much of the water will not affect the outer channels of the air, or the outer channels of the IC. Yes the water will be ingested in the engine, but much of the charge cooling effect will go to waste.

The last step in the installation is is the nozzle placement. Normally putting the nozzle before the IC is better, when the IC is in a bad place, or is very small. So the Mini should have the nozzle before the IC. The only problem with putting it before the IC is that there is no good place that will distribute the water over the charged air in the tube equally. Because of the wide opening, if we put the nozzle in the center, much of the water will not affect the outer channels of the air, or the outer channels of the IC. Yes the water will be ingested in the engine, but much of the charge cooling effect will go to waste.

After the IC was a better choice as it iwas better centered over the boost tube, and would deliver water better to the complete charge. Since it was closer to the cylinders, it would also have better in-cylinder cooling. The only thing it may not effect is the charge temps. But we will have to see!

After the IC was a better choice as it iwas better centered over the boost tube, and would deliver water better to the complete charge. Since it was closer to the cylinders, it would also have better in-cylinder cooling. The only thing it may not effect is the charge temps. But we will have to see!

BASE RUN-shows base power as we might expect from these parts.

BASE RUN-shows base power as we might expect from these parts.

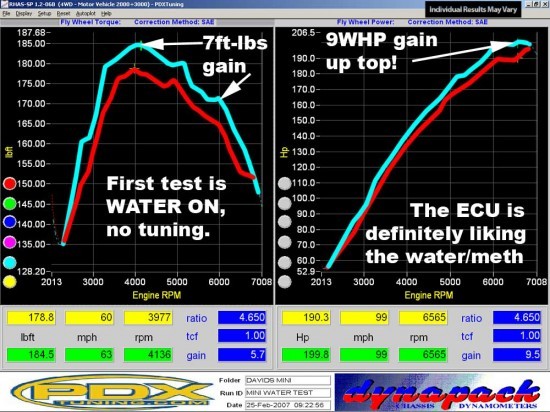

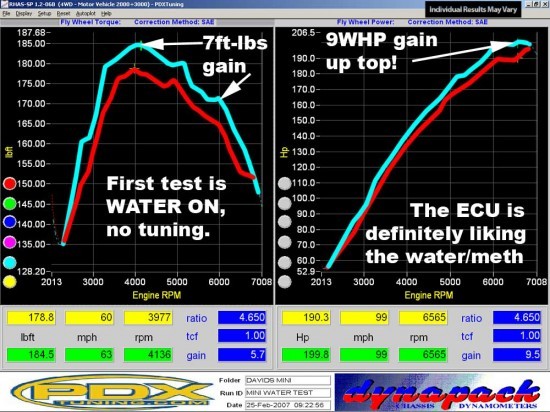

RUN WITH WATER ON- shows that the ECU is happy with WI on, and no tuning. Similar results might be had be race fuel.

RUN WITH WATER ON- shows that the ECU is happy with WI on, and no tuning. Similar results might be had be race fuel.

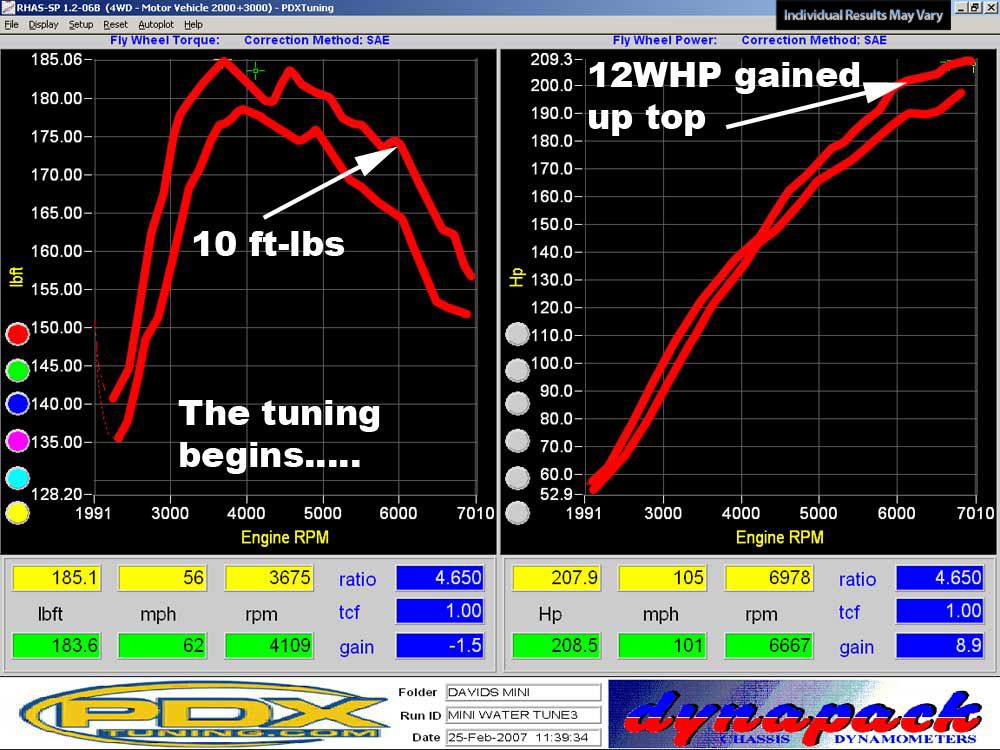

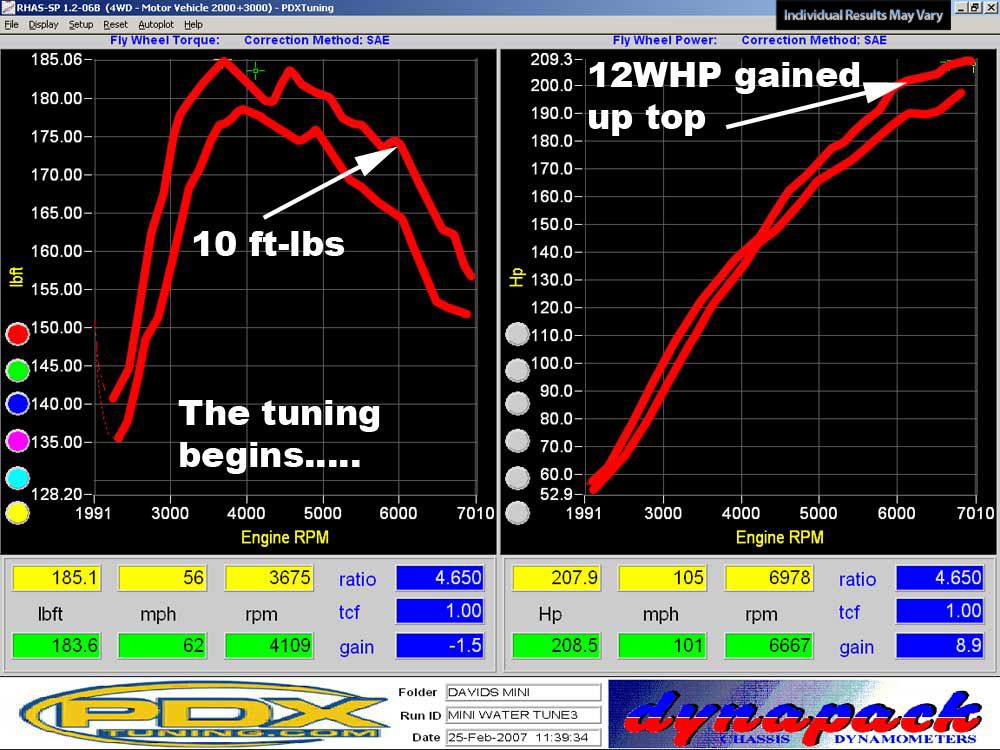

RUN WITH SOME FUEL TUNING- got some smoothing to do, and there is definitely more power to be had.

RUN WITH SOME FUEL TUNING- got some smoothing to do, and there is definitely more power to be had.

RUN WITH FINAL FUEL TUNING, solid consistent, safe gains.

RUN WITH FINAL FUEL TUNING, solid consistent, safe gains.

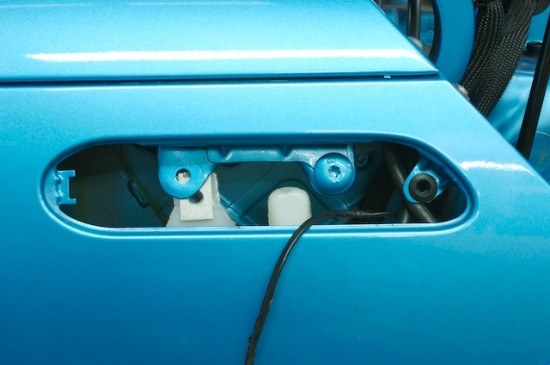

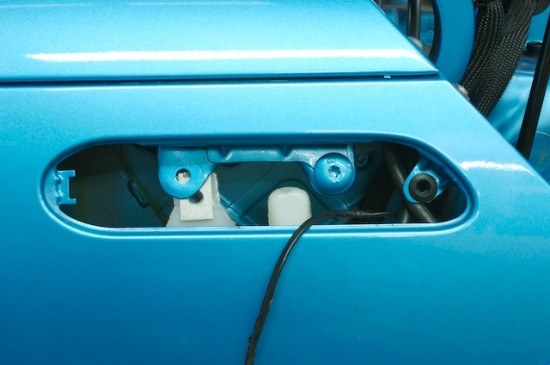

INSTALLATION

There are a few good places to install the WI system in the Mini, but we chose a place that is both functional and shows off the system. With the install we choose to use the window washer tank (passenger side tank). Because the tank is much lower than the pump assembly, we will have to use a primer pump. We thought we would use the OEM pump assembly to be the primer but the problem is wiring it up, and using diodes to do this wasn't going to be a job for everyone. So we used an off the shelf windshield washer pump from NAPA for about $14. Next was to remove the fender liner to get to the tank. The tank is a little tricky to remove, but once you figure out that there is a hidden connector (below) it comes out very easy. After drilling an tapping a 1/8NPT fitting into the bottom of the tank we are ready to re-install it back into the car. Next up is the primer pump install. This is a pretty simple job. Drilling a couple of holes to mount it, and connect the tank hose up to it and we are done. Wiring the pump is simple. The PWi-1 has 2 wires ready to go, so all we have to do is extend the wires to the pump.

After drilling an tapping a 1/8NPT fitting into the bottom of the tank we are ready to re-install it back into the car. Next up is the primer pump install. This is a pretty simple job. Drilling a couple of holes to mount it, and connect the tank hose up to it and we are done. Wiring the pump is simple. The PWi-1 has 2 wires ready to go, so all we have to do is extend the wires to the pump.

With the fender liner back in its time for the pump assembly and and wiring job. The pump assembly fits great in the window cowl area, and it is very easy to get a drill in there for the mounting holes. Besides the normal positive and negative connections, the only tricking connection is the fuel injector ground signal. This connection is important as this is how the PWI-1 picks up fuel injector duty cycle and determines how much water to inject.

With the fender liner back in its time for the pump assembly and and wiring job. The pump assembly fits great in the window cowl area, and it is very easy to get a drill in there for the mounting holes. Besides the normal positive and negative connections, the only tricking connection is the fuel injector ground signal. This connection is important as this is how the PWI-1 picks up fuel injector duty cycle and determines how much water to inject.

All done!

All done!

The last step in the installation is is the nozzle placement. Normally putting the nozzle before the IC is better, when the IC is in a bad place, or is very small. So the Mini should have the nozzle before the IC. The only problem with putting it before the IC is that there is no good place that will distribute the water over the charged air in the tube equally. Because of the wide opening, if we put the nozzle in the center, much of the water will not affect the outer channels of the air, or the outer channels of the IC. Yes the water will be ingested in the engine, but much of the charge cooling effect will go to waste.

The last step in the installation is is the nozzle placement. Normally putting the nozzle before the IC is better, when the IC is in a bad place, or is very small. So the Mini should have the nozzle before the IC. The only problem with putting it before the IC is that there is no good place that will distribute the water over the charged air in the tube equally. Because of the wide opening, if we put the nozzle in the center, much of the water will not affect the outer channels of the air, or the outer channels of the IC. Yes the water will be ingested in the engine, but much of the charge cooling effect will go to waste.

After the IC was a better choice as it iwas better centered over the boost tube, and would deliver water better to the complete charge. Since it was closer to the cylinders, it would also have better in-cylinder cooling. The only thing it may not effect is the charge temps. But we will have to see!

After the IC was a better choice as it iwas better centered over the boost tube, and would deliver water better to the complete charge. Since it was closer to the cylinders, it would also have better in-cylinder cooling. The only thing it may not effect is the charge temps. But we will have to see!

AFC NEO INSTALL

This is the one part of the whole install that is not for everyone. This requires cutting of ECU wires, and some soldering. Along with the install comes tuning, which needs to be done by a professional. This physical installation isn't very hard. Basically there are 5 wires to tap/cut into and then mounting of the head unit. From there is where it gets tricky. Tuning the ECU is not something for everyone. Besides having a dyno, and the tools to measure things like knock, AFR, and temps, the knowledge needed to adjust parameters is priceless. This is where you need to take your car to someone that knows what they are doing.DYNO TIME

During the test we ran multiple runs for all changes. This ensures that the engine temps have stabilized, and proves the changes we were making. First off we did 7 base runs to get a good base number. BASE RUN-shows base power as we might expect from these parts.

BASE RUN-shows base power as we might expect from these parts.

RUN WITH WATER ON- shows that the ECU is happy with WI on, and no tuning. Similar results might be had be race fuel.

RUN WITH WATER ON- shows that the ECU is happy with WI on, and no tuning. Similar results might be had be race fuel.

RUN WITH SOME FUEL TUNING- got some smoothing to do, and there is definitely more power to be had.

RUN WITH SOME FUEL TUNING- got some smoothing to do, and there is definitely more power to be had.

RUN WITH FINAL FUEL TUNING, solid consistent, safe gains.

RUN WITH FINAL FUEL TUNING, solid consistent, safe gains.