The term uppipe, where did this come from? Definitely not from Subaru, but most likely from some crazy Subaru Enthusiast. Where ever this term came from, I remember first seeing the term use on I-Club forums (now known as NASIOC). This strange part people were calling an Uppipe is what drove me to start coming up with high performance parts for Subarus.

Over the years I have this term so much that I added it to my Microsoft Word Dictionaries. The term was so well taken that I have never seen another "Uppipe" on another car, and to this day, this term is well recognized as a part you can buy for your Subaru. Its easy to see how people came up with this name using a downpipe as an example. This term came about because turbos are always mounted somewhat high on the engine and the exhaust pipe coming of it always goes "down", hence the name downpipe. Since the turbo on the Subaru is mounted high, and the exhaust ports are on the bottom of the engine, there is this wonderfully simple pipe that goes from the header "Up" to the turbo. Ding! The Uppipe it is!

The whole Uppipe craze started in the US because our 2002 WRX was the first WRX ever to come with a Catalytic Converter mounted BEFORE the turbo! Now it is illegal to remove a cat from a car, but the difference was so huge on these cars that people didn't care and wanted to get rid of it!

The First PERRIN Uppipe

Before I ever thought about making aftermarket car parts I was just a normal (well maybe crazy) Subaru enthusiast that installed parts on friends car for fun, one of which was the Uppipe. None of them really fit well, and they all had issues with the EGT sensor coming out over time. These ill-fitting problematic parts is what drove me to do what I do today!

|

Original PERRIN logo

Thanks to my friend Mitch Morse for helping design this logo. It |

|

Uppipe #20-ish......

I say "ish" because i never numbered them, but its very close to #20. This part was a returned from a customer who bought a rotated turbo kit and didn't need this anymore. Its amazing the condition of this part is so good, except the missing logo! |

The start of my Subaru Performance-ing was driven by the lack of quality parts available to us. Starting with the Uppipe, and knowing the problems that existed, i felt i was in a good position to build something that no one else had. I made the EGT bung properly so it wouldn't come out, I accounted for the shrink that happened after welding the 321 Stainless Steel (so no flex joint was needed), made it the right size and provided super detailed instructions. This made the PERRIN Uppipe a flawless fitting part and also made it hard to keep up with demand!

What makes the PERRIN Uppipe the best........

Dyno Proven

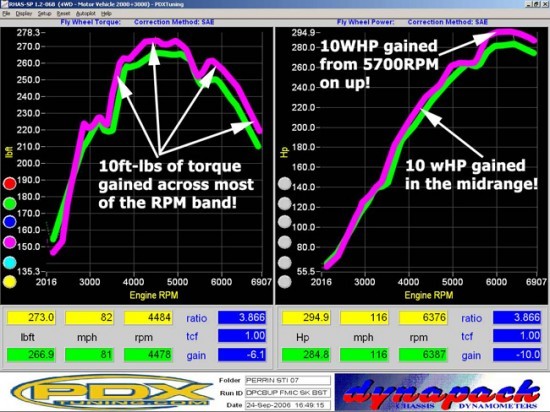

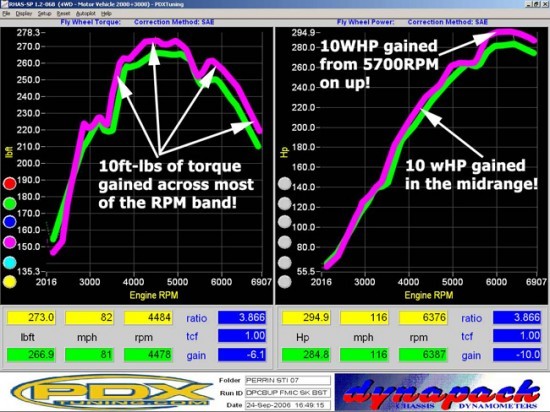

We were the first to provide hard back to back data that a PERRIN uppipe makes power on an STI. This is very important to understand because it was once thought that that an aftermarket catless uppipe wouldn't make any more power than the stock catless uppipe found on STI's. We proved this to be wrong. It was a surprise to us also, but during some heavy testing on our STI, we did a quickly swaped out the OEM catless uppipe with the PERRIN Catless Uppipe. It made a repeatable 10WHP! WOW! This was on a completely stock ECU tune! We prove our parts on our dyno, not with a flow bench.

|

Proven 10WHP

This test was done on one of our STI's runing in stage 3 form but with the stock ECU tuning. Imagine if we had an ECU tune before and after! Again this proves the PERRIN uppipe works on all Subaru turbo cars! |

Material

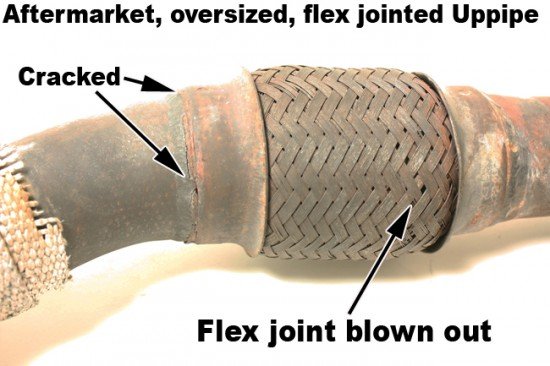

First and foremost is the material choice. We have always used 321 Stainless Steel, which is one of the highest quality materials best suited for exhaust systems. Its ability to deal with extreme temps and vibrations make this perfect for this part. Many companies use lesser 304SS and then a flex joint to deal with the vibrations and expanding and contracting only to find either the flex joint blows out, or a crack developes.

|

321 Stainless Steel...

This part was in service for roughly 6 years and its amazing how nice this part looks. This is one of the great properties of 321 SS, its resistance to corrosion! |

Tubing Size

From the beginning of time I would see these Uppipes where people would just make them as big as they can, or make them to match the size of the gaskets. Which is completely is the wrong way to approach this. The important thing is exhaust gas velocity, and keeping it the same or speeding it up slightly. Since the first Uppipe we have made the ID of the pipe best fit the OEM Exhaust manifold and turbo inlet. Its not a huge secret but the 1.75" tubing we use is the best size to use for the Uppipe on cars that use stock headers and stock location turbos. This matches the ID of the OEM exhaust manifold so the speed of the exhaust gases don't slow down (going into a bigger tube) or speed up and get restricted (going into a smaller tube).

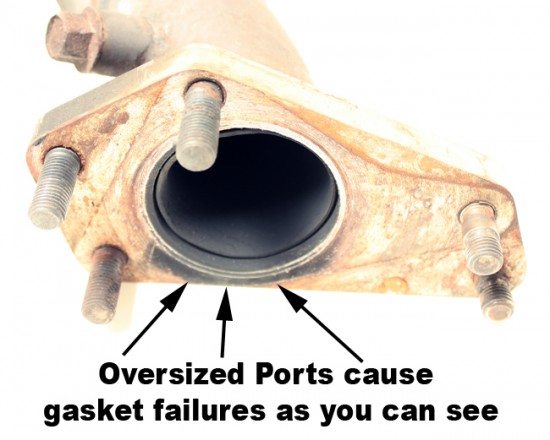

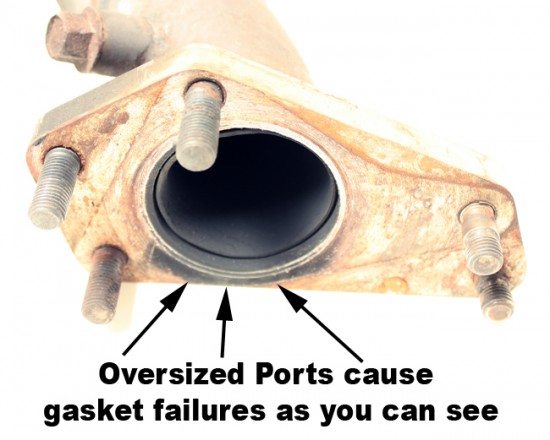

Port Size

Because we use the proper size tubing it also means we have proper sized ports. The OEM gasket is a very high quality gasket and its designed to sit back from the extreme temps of the exhaust. When you over-port your flanges the OEM gasket is now exposed to the extreme temps and will burn out very quick. You can see below an example of an oversized/overported Uppipe that has issues with both ends of the flanges sealing. This customer tried new gaskets and even using RTV to seal it up!

|

Proper Sized Ports

In this example of a used PERRIN uppipe you can see the carbon ring left behind indicating no leak from the gasket. This is what we commonly see on all PERRIN upippes no matter how long they were in use. |

|

Overported Flange

In this example of a brand X uppipe you can see the carbon has blow out past the gasket. This is because of the fire ring on the gasket being too close to the extreme exhuast temps. In all these situations its just a matter of time before the gasket is blown out. |

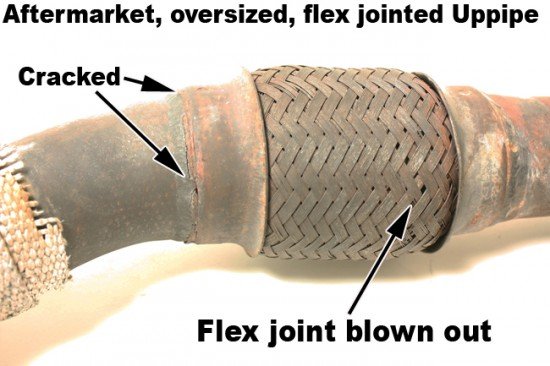

No Flex joints

In years of research we have never found a flex joint manufacture that rates a flex joint to 1600F continuous at 40PSI. This is why all Uppipes that use flex joints eventually give out! The problem is the flexible part of the flex joint consists of very thin layers of Stainless Steel. These super thin "bellows" don't hold up to temps that cause steel to glow red hot while being under the pressure you exhaust sees under heavy load. Eventually they fatigue and blow out.

|

Flex Gone Bad!

In this example of a brand X uppipe that had a flex joint blow out. What is amazing is that you can see right through the outer cover of the flex joint because the hole is so big! This part was in service for roughly 3 years before this happened. After the part was removed, we also found a few cracks. |

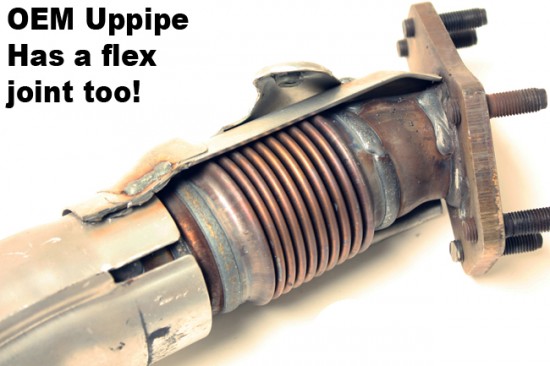

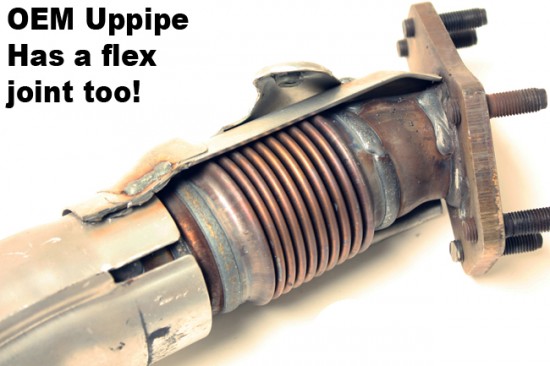

Guys that use the OEM Uppipes in race conditions also find that they don't hold up, because they too have a flex joint in them. You may not know this, because it's buried under all those heat shields! The only reason why the stock part holds up for a reasonable amount of time is that there is a shield on the inside to help deflect heat away from the fragile bellows.

|

OEM has a flex joint!

In this example of a stock STI uppipe. I cut off the sheild to show that a flex is installed on these also. Under normal conditions these hold up ok, but start putting more boost and bigger turbos, and these start to blow out just like the aftermarket ones. |

Most companies use flex joints on their Uppipes to solve fitment problems. We solved this problem years ago by just making the part properly. On a part like ours that fits solidly between two solid points, it's important that it fits perfect! While this takes extra effort to ensure a proper fit, it something you can see others skimp on and just add a cheap flex joint that is not rated to do the job. This allows the part to fit even if the fabricator made it wrong. What you can't see is on the Aftermarket Uppipe we show above is the offset in the flex joint. This shows how it was not fitting good but the flex joint made it fit. BAD NEWS!

Flanges

We started out with 3/8" Laser cut 304SS flanges then quickly moved to ½ thick flanges. This was done because of the flanges warping when welding. It happens no matter what, but bumping up the thickness to ½" and CNC machining them (not laser cutting which added heat) controls this problem to an absolute minimum. A small feature to our parts is that the flange warps away from the mating surface which is GREAT for helping thing seal up! So if you get a PERRIN Uppipe and you see the flange is slightly warped, don't worry its not flattened out for a reason!

One more thing we do is face our flanges. During the machining process a second step is taken to face-off or mill-off the main mathing surface. This removes the rough mill finish to ensure a perfect seal between your header and turbo. This is a time consuming step in the machining process but once again, is worth it to ensure your PERRIN Uppipe is perfect!

|

CNC Machined Flanges

Only 1/2" thick 304SS flanges used here. You will never see Chrome plated Mild Steel flanges on a PERRIN part. Tha is left for the imported brands. Now, the back side of our flanges are counterbored to make the transition for the exhaust smoother! |

|

Counterbored Flanges

Now all the flanges are counterbored to create an even better smoother airflow path. You can see how the tubes meets the flange in smooth fashion!

Also you can see the perfect flat "faced-off" mating surface. Not something you see often. |

Welding

Look at a PERRIN Uppipe you will only see one weld on each flange. We see many uppipes with welds on the inside and outsisde and like clockwork, they crack. This is because when you weld SS it shrinks. Welding on one side then the other causes huge amounts of stress on that short little piece of tube between the welds. Its just a matter of time before it causes a crack. Cracks are bad as this causes a leak in the exhaust loosing precious exhaus pressure, which means bye bye boost!

|

One Weld to Rule Them All

You will only find a perfect single weld on each end of our uppipe. Two welds on each flange just means a crack in your uppipe is inevitable! |

No EGT Bung!

Since most owners we sell these to are STI or 06+ WRX owners this won't matter at all. But all the 02-05 WRX owners (as well as some Legacy GT guys) will feel comfortable knowing their OEM EGT sensor is not installed on our part. This seems crazy to defeat a sensor on the car, but these older WRX' are known for EGT sensors to fail. When they fail the small metal probe flies into the turbo and destroys it! Then bye bye turbo and say hello to an expensive trip to the dealer. After the first initial run of Uppipes we ditched the EGT sensor altogether. Instead, a small resistor was put in place of the sensor to keep the ECU from throwing a CEL. This saved many turbos from going bad as well as kept the sensor from potentially coming unscrewed.

|

Don't let this happen!

On any modified 2002-05 WRX's the OEM EGT sensor (located in the upipe) can break off and destroy the turbo! Using a PERRIN uppipe protects the turbo from damage by removing the sensor all together. This irrelevant sensor is only there to tell the ECU the catalytic converter is too hot. Since the PERRIN uppipe removes the cat on the 02-05 WRX, it no longer needs to use the sensor. |

Bends

Using the feature "Mandrel Bent" is kind of a no-brainer. In this day and age, if you don't use a CNC Mandrel Bender to bend your pipes you are living in the dark ages! But where we one-upped the competition is by making tube have 2 bends not just one which makes for a super tight restrictive bend. The 2 bends made for a much smoother path from the header to the turbo. We were the first to make the par this way and you can tell how others followed by looking at the Uppipe and how similar to ours.

|

CNC Mandrel Bent

That is all that needs to be said, CNC Mandrel bent on a Pines #2 machine. |

The PERRIN Uppipe Today

Do a search for Uppipe and you will see we are always mentioned a few times on the first page. We feel pretty proud of this, but over the years we have seen many different brands pop up pushing us down on the list. While we were one of the first Uppipes available in the US, the competition has risen on this simple, somewhat forgotten part.

I say forgotten because there hasn't been a Subaru produced with a cat before the turbo since 2005. Which means, the need for this part has lessened over the years. A few years back we dynoed our Uppipe on an STI. In this back to back test (the only ones to ever do this) we were very surprise to find 10WHP when swapping out the OEM catless Uppipe for a properly sized PERRIN Uppipe! This dyno test is still our best selling tool today because it represents 90% of the customers we sell Uppipes to.

Now we have stepped it up one more time with new flanges. The ½" thick, faced, 304SS flanges with counterbores on the back side, makes our uppipe better than its ever been and also the most powerful its ever been. While these features add a bit of cost on our end (not yours) its worth it to us to keep our Uppipe the most sought after Uppipe on the market! Maybe you too can add the word Uppipe to your Microsoft WORD Dictionary.

Over the years I have this term so much that I added it to my Microsoft Word Dictionaries. The term was so well taken that I have never seen another "Uppipe" on another car, and to this day, this term is well recognized as a part you can buy for your Subaru. Its easy to see how people came up with this name using a downpipe as an example. This term came about because turbos are always mounted somewhat high on the engine and the exhaust pipe coming of it always goes "down", hence the name downpipe. Since the turbo on the Subaru is mounted high, and the exhaust ports are on the bottom of the engine, there is this wonderfully simple pipe that goes from the header "Up" to the turbo. Ding! The Uppipe it is!

The whole Uppipe craze started in the US because our 2002 WRX was the first WRX ever to come with a Catalytic Converter mounted BEFORE the turbo! Now it is illegal to remove a cat from a car, but the difference was so huge on these cars that people didn't care and wanted to get rid of it!

Over the years I have this term so much that I added it to my Microsoft Word Dictionaries. The term was so well taken that I have never seen another "Uppipe" on another car, and to this day, this term is well recognized as a part you can buy for your Subaru. Its easy to see how people came up with this name using a downpipe as an example. This term came about because turbos are always mounted somewhat high on the engine and the exhaust pipe coming of it always goes "down", hence the name downpipe. Since the turbo on the Subaru is mounted high, and the exhaust ports are on the bottom of the engine, there is this wonderfully simple pipe that goes from the header "Up" to the turbo. Ding! The Uppipe it is!

The whole Uppipe craze started in the US because our 2002 WRX was the first WRX ever to come with a Catalytic Converter mounted BEFORE the turbo! Now it is illegal to remove a cat from a car, but the difference was so huge on these cars that people didn't care and wanted to get rid of it!