Category : Dyno Test & Tune

Back to Blog

Share This

NEEDS TEXT FROM NASIOC

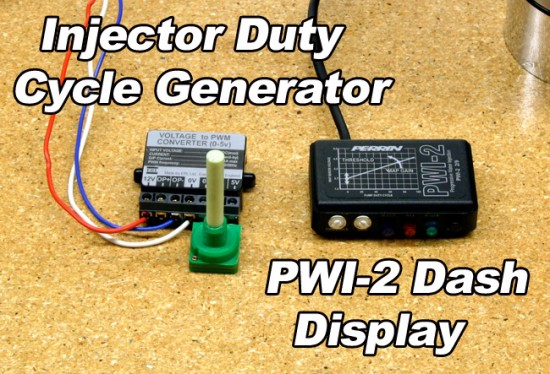

Here is a pic of our test fixture we built to do this test:

Here is a pic of our test fixture we built to do this test:

Progressive-ness of the PWI-2 system.

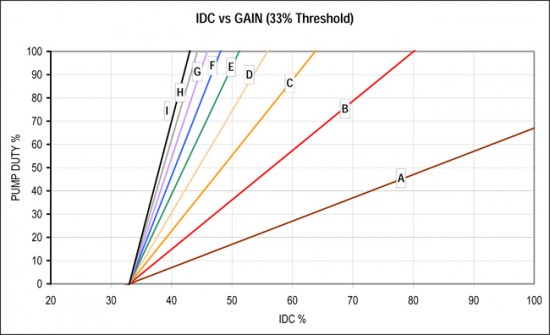

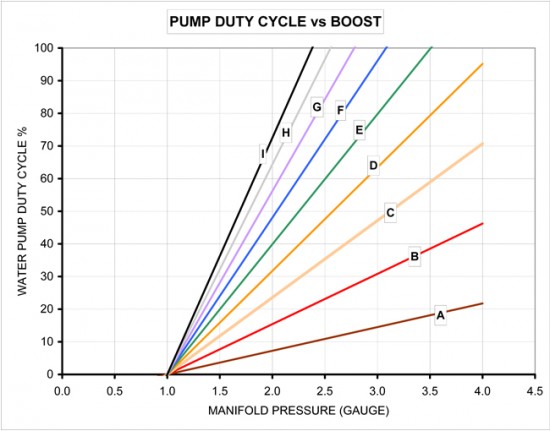

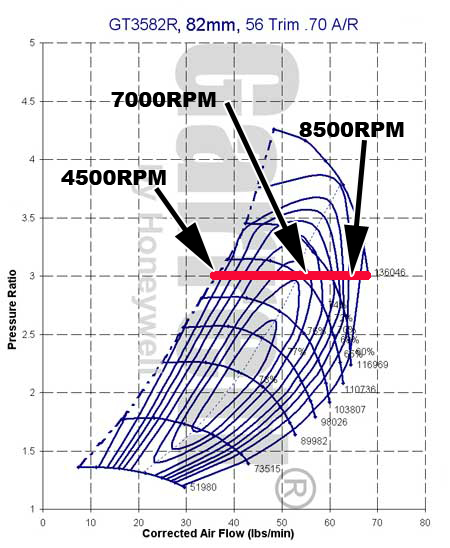

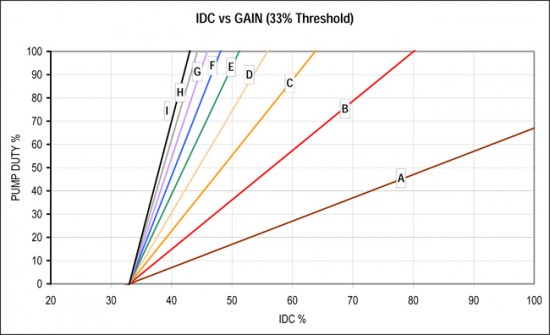

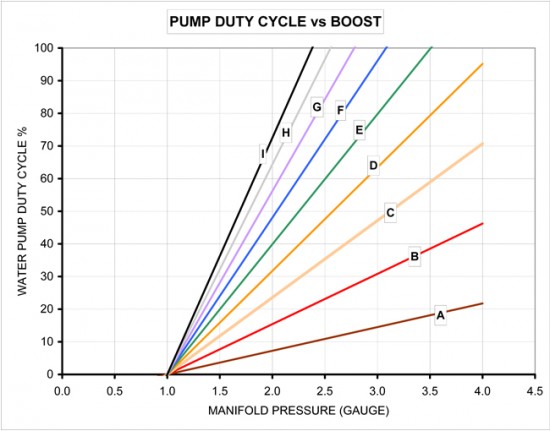

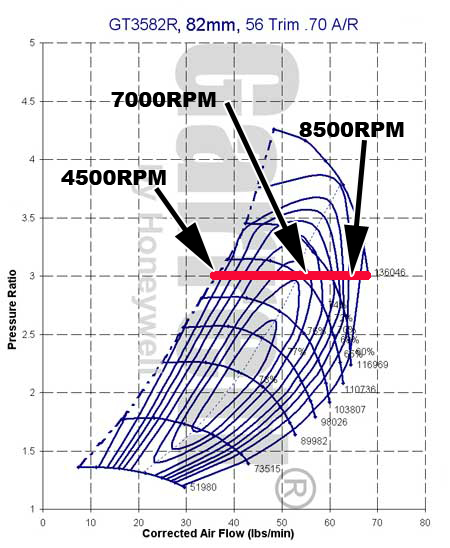

The PERRIN PWI-1 system stood out amongst competitive systems because of it being one of the first truly progressive water injection systems. The new PWI-2 is still just as progressive as the older system but it stands out from the crowd for a few other reasons. Less expensive non-progressive systems are simple and cheap, and are restricted to a fixed volume of water that can be delivered. These systems suffer from too much water at lower RPMS and not enough water at higher. This can cause a loss in power, at both lower RPMs (too much water) and high RPMS (no detonation control). The PWI-2 system is progressive which means it injects a varying amount of water/methanol depending on the engines load. Meaning it will inject the same % of mixture versus fuel throughout the entire RPM and load on the engine. This means no loss in power down low because of too much being injected, and no loss in power up top due to less flow. So in other words you want progressive!Progressive using IDC or 0-5volt input

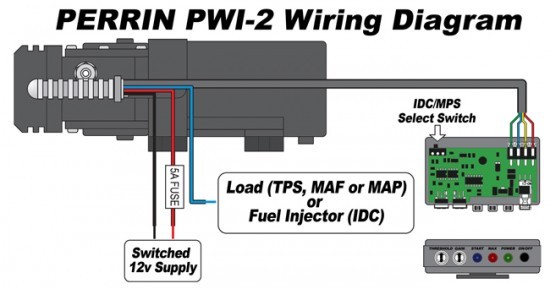

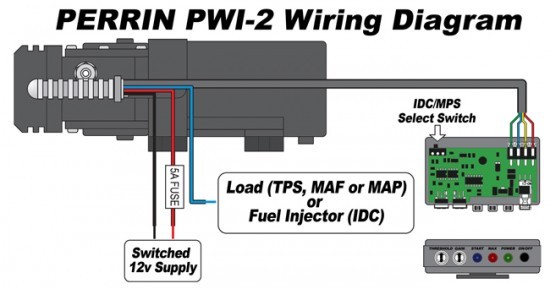

The PWI-2 gets its progressive nature by reading engine load one of 2 ways, IDC or a 0-5volt signal. There are many other "progressive" systems out there that use the 0-5volt signal from a MAP sensor to become progressive, this is not where our systems stands out. While we included the 0-5v input, this was the secondary method of it picking up engine load. IDC or Injector Duty Cycle is the primary method the PWI-2 was designed to pick up load. This is not common amongst the other water injection systems out there because of the added costs and design. While this is the case, it is the best way to pick up load. Why, because engine load is based on fuel. More engine load (boost, RPM,TPS, Hills......) means more fuel needed. Since the PWI-2 injector water/meth based on fuel flow it becomes very easy to inject the recommended 10-20% mixture of water/meth vs. fuel flow. When using the 0-5volt input (like most of the competition does) on a MAP sensor (boost) the system will only inject more with more boost. This means once the system hits its peak boost, additional water/meth will not be injected. This is not truly progressive even though some of the competition calls this progressive. Some of the completion adds an RPM pickup to add a more progressive nature to the system. While this works, this adds more parts, more install time, and sometimes additional parts need to be purchase to pick up the tach signal properly. Then add to all that is the need to "map out" the injection. Again more time, and more setup. Using IDC (Injector Duty Cycle) eliminates all these added steps and costs, which is why the PWI-2 uses this to start with. Don't be fooled by progressive systems that use only a 0-5volt input to be "progressive". After all that, the PWI-2 brain takes the input signal and varies the voltage to the pump to control how much it flows. IT does this by pulsing (at high frequency) 12 volts to the pump creating a simple and accurate way to drive the pump at different speeds.NEW High Pressure High volume Pump

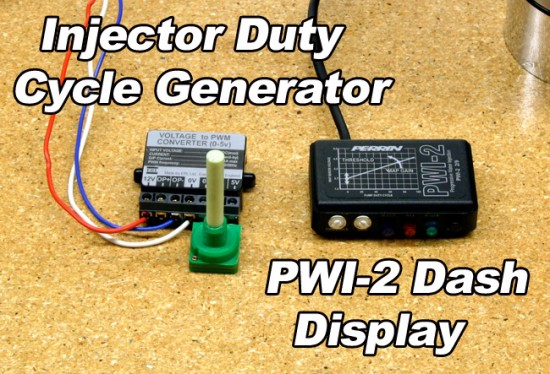

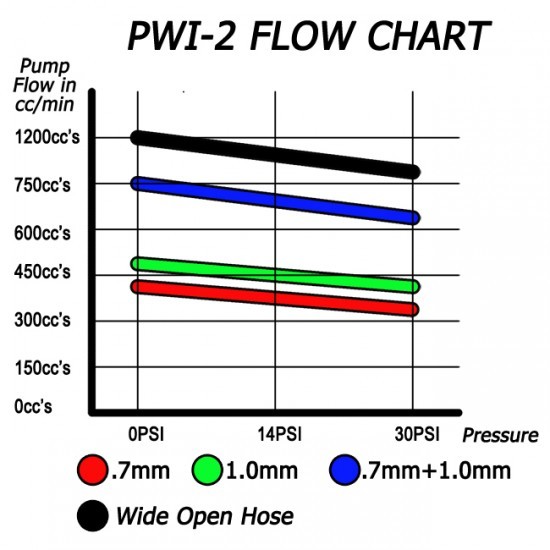

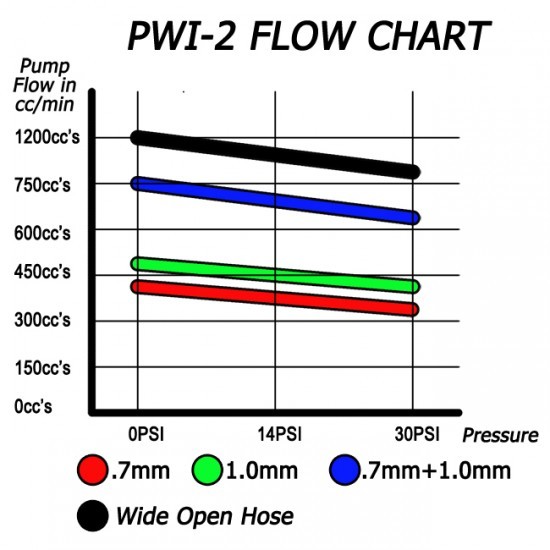

Our PWI-1 system used a very high quality, expensive high pressure pump, which worked great, but lacked in one department, flow. This pump could only flow about 320cc/min of flow, which not quite enough for guys making huge power. So one thing we wanted to make sure we did when making the PWI-2 system is to include a pump that flowed more than the first one, and was less expensive. Well we did it! This new pump is smaller, lighter, less expensive, flows more, and quieter! So what is the downfall to this new pump? Nothing, other than we do not recommend running 100% methanol through it. How does this pump compare to other pumps on the market? This is a diaphragm style pump that uses a motor driven pump head, which is like others out there. But where our pump shine brighter than the rest is in the size and looks. Nearly all the completion uses the common Shurflow pump. This pump is HUGE heavy and ugly. None of which we feel our pump is. Even if you can get over the looks, there is one huge flaw when using this pumps, the pressure switch. These Shurflow pumps have a pressure switch that cuts power to the pump when the pressure exceeds a set amount. This is bad because these systems runs at pressure that constantly bump this switch on and off. This causes a fluctuation in water/meth flow and also makes it very inconsistent to tune. The PWI-2 pump doesn't have a pressure switch at all, as it doesn't need one. So you get smooth consistent flow from the system. Something your tuner will love! We spent a lot of time with water injection systems over the years and one thing we realized is no one had actual data on how much there systems flowed in real world applications. We first tested the PWI-2 using a custom built Injector Duty Cycle generator (thanks Richard at Aquamist) to first show how much the pump flows at different injector duty cycles (different loads). We then tested how much the system flowed with no nozzle, with a .7mm nozzle, 1.0mm nozzle, and dual 1.0mm & .7mm nozzle. Then we added boost!! We tested the 1.0mm nozzle under 14psi and 30psi of boost, then did flow testing with the dual 1.0mm nozzle and the .7mm nozzle. The results are for sure impressive and for sure not something ANY other water injection system manufacture has done before. Here is a chart showing the pump flow at different PSI's. Here is a pic of our test fixture we built to do this test:

Here is a pic of our test fixture we built to do this test:

NOZZLES

Proper atomization of water is crucial. A poorly designed nozzle can cause an unequal mixture delivery to each cylinder, or worse hydro-lock your engine. The tried and true Aquamist nozzle is the standard from which other systems are judged from. These nozzles have a special swirling action that causes the water/methanol mixture to come out in a very fine mist. Even the huge flowing 1.0mm nozzle has a near perfect atomization because of the design. To maximize the performance of the PERRINTM water injection system, the kit includes 2 precision Aquamist nozzles. Choose from the included 1.0mm, and .7mm nozzles, which will cover flow rates needed to support 250-600 horsepower. (Other nozzle sizes available see your PERRINTM dealer) Each PWI-2 kit includes a nozzle seat. This seat has a 1/8NPT fitting on one end allowing easy installation of the injection nozzle into your boost tubes. The nozzle seat allows for quick, simple change of different nozzle sizes without wearing out the threads in the boost tube. Simply drill and tap a 1/8NPT hole in your boost tube, screw in the nozzle seat, and decide which nozzle to use and your off!Packaging

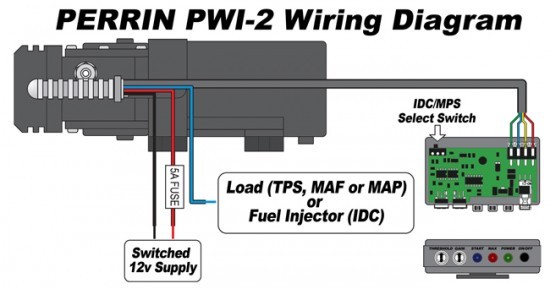

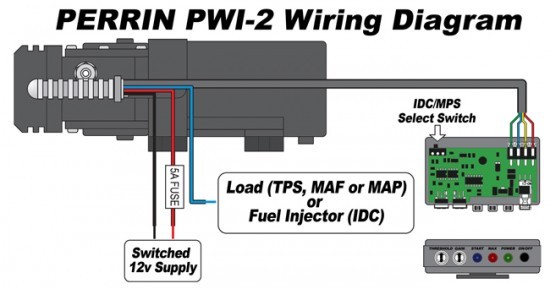

The PWI-2 system has two main components. Pump assembly, and Dash display. We have simplified the system compared to the old one to make installation simpler. Besides these parts, you have 3 wires to hook up to the car and 1 harness to the display and your done! With proper planning the system can be installed in roughly 2 hours!Pump Assembly

The pump assembly consists of the pump & head with built in electronics for controlling the pump. The 4 rubber legs provide easy installation and a near noise free operation. That and 4 wires come off the pump, very simple!Dash Mount Display

The dash mounted display contains the brains to make the system work, 2 trim pots to adjust the setting, a few LED's to give you an idea what is going on and an on/off switch. The trim pots control when the water/methanol starts to flow (based on IDC or load) Inside the Brain Box are three trim pots to fine tune the injection start points, pump gain, and nozzles flow rate. Additionally, the box contains a terminal for the dash controller wire harness and a multi-screw connection terminal allowing the main wire harness to be trimmed to any length for a clean install.