Category : Dyno Test & Tune

Back to Blog

Share This

Proven Wheel HP from 3.0"

Of all the things I see on the fourms, the one comment that stuck out was, "3in may make more HP, but there is a point of diminishing returns." I 100% agree, and for sure this is the case, but the point of diminishing returns is where? All I see are people guessing, people saying "I heard this or that", "Well this tuner SAYS 2.5" is best", but again ZERO proof of this. We feel the answer to that question is 3" for virtually any turbo car. How can we say this? Simple, experience.

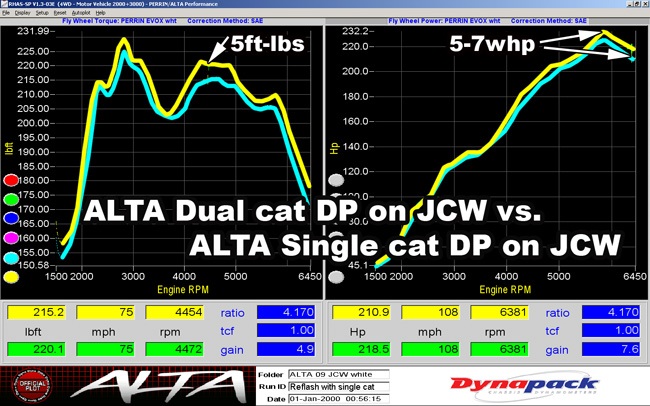

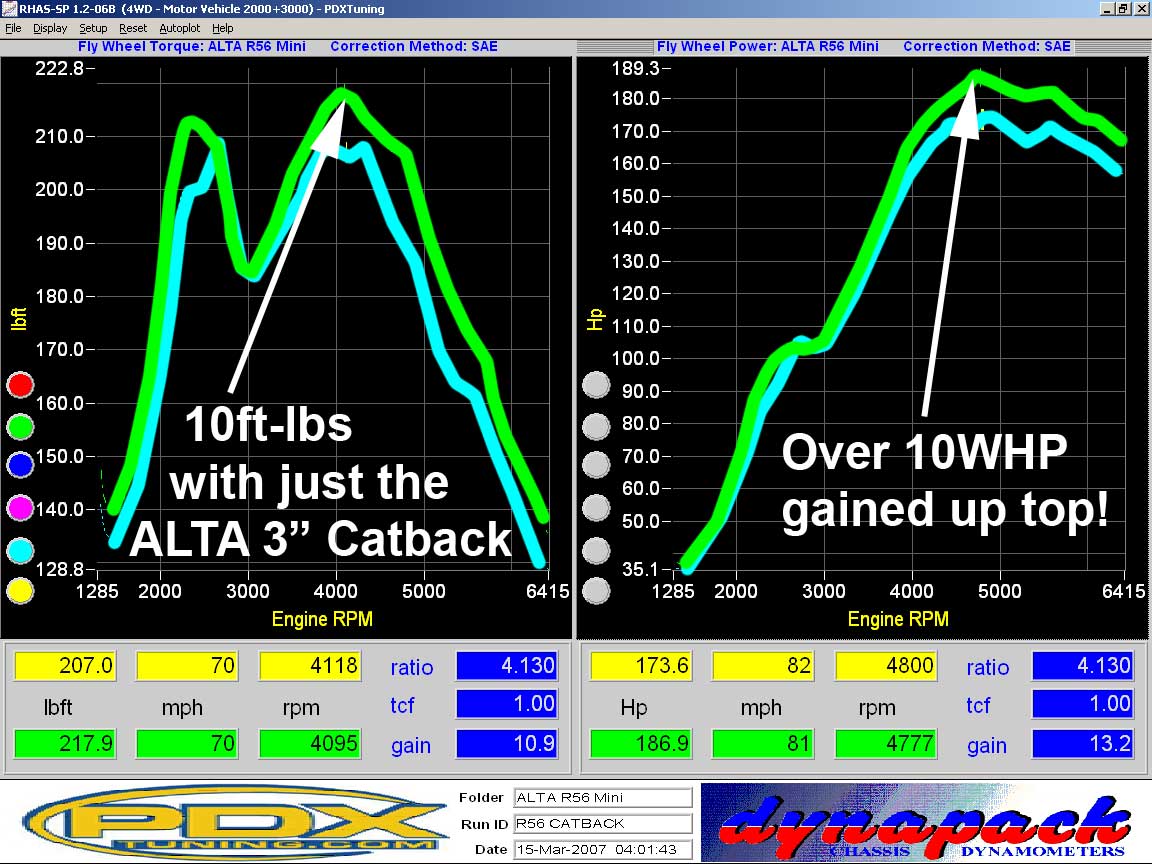

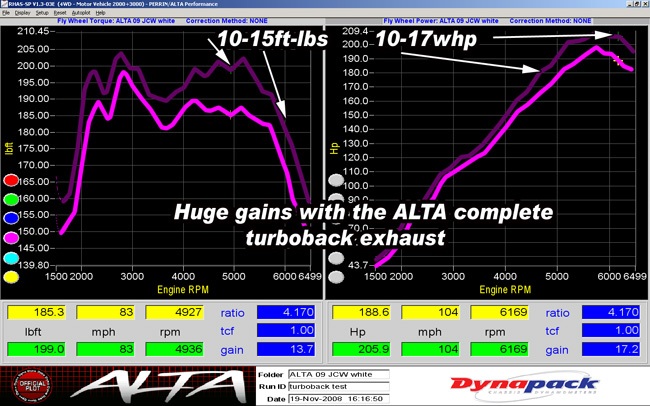

Here is a dyno graph showing our 3" dual cat system ran on our otherwise stock JCW and MCS.

First off, we are dealing with turbocharged cars not normally aspirated. So the rules of sizing really get thrown out the door. Its a given in the forced induction world that bigger is better. Read any book about turbo vehicles, they say if it fits and its not too loud put on a biggest size you can afford. Turbos don't want back pressure as this slows the turbos response. Because turbo cars have lower compression, the sooner you get it making boost the sooner you have torque, the more torque at a given RPM means more HP. For the last 10 years we have seen this over and over again, and today continues to be a rule of thumb. We have actually done a test on 2.25", 2.5" and 3" exhausts on a 1.6L forced induction engine. We did dyno testing on our R53 with 15% SC pulley comparing stock to threes sizes. The 2.25" exhaust made about 3-5WHP, the 2.5" system made about 10WHP, and the 3" made about 12-13 WHP. On this car we opted to push normal customers to the 2.5" system because of sound more than anything. These cars are much louder than the R56 because there is no turbo in the exhaust killing some of the sound. Keep in mind that during these tests, the boost on this engine was only 10psi at 3000RPM and 14psi at 6800, making only 190WHP. On the R56, we are running 18-ish peak boost at 2000 and 16 or more at 6500 making around 220WHP. The turbo cars are making 50-80 more WHP at 4000 than the SC cars. More HP means more airflow. If the 2.5" theoretical exhaust system is good enough, then why do we still gain more HP on cars removing a high flow 3" cats from our 3" exhaust system? Simple there is still a slight restriction on our 3" (too big) turboback exhausts using two high flow cats. When the JCW R56 came out we had customers asking for a single cat exhaust for them and of course some dyno numbers to see how much better it is. You can see below the results we found. Keep in mind this is showing the ALTA 3" Turboback dual cat system versus the ALTA turboback single cat system.