Category : Dyno Test & Tune

Back to Blog

Share This

As promised here is our data! Sorry if the formating is a little confusing.

Good to hear from Matt, we havne't heard from you lately. Must be all those MC2 articles!

First off, i know understand why there are lots of doubters out there. It could be because our dyno graph wasn't on our site. When we had an issues with our pictures on the server, this one got missed. On these test conditions, the OEM Intercooler was tested with the hood down as was the V2. The fan we use is not some super over powering fan( that would blow too much air), but one we feel does a good job providing a good middle ground for air flow.

This test was on our 04 shop car. It had stock ECU programming (obvious by the redline), 15% pulley, ALTA intake, ALTA header, ALTA 2.5" Catback exhaust. If we had a way to raise the redline a bit, then further gains will be seen. The IC we used here was one with the cast tanks, and 12/12fpi.

So when we gave Matt our IC€™s to test, we gave him our normal Classic intercooler, and our V1 ALTA flow through. Its important to note a few things with the ALTA V1 flow through. The tanks were made using parts of our old IC and some sheetmetal. The core was our first prototype core that was a 12.5"L x 2.9"H x 8"D core using 12 fins per inch (very important to note) on both hot and cold sides. This was our first attempt at the core, and Matt was the first to get it and the first to use it!

Here is the data in rough form from Matt. There is tons more data, but his is enough for you all to see.

Intercooler_____ Average Peak Mass_____ Ave IC efficiency_____ Average Cells with Knock_____Pressure Delta_____ Average Peak HP

Stock _____________714.1_____________ 64.2%_________________7.3 _____________________12.7_____________ 166.4

ALTA TMIC_________708.1______________61.0%________________5.4_____________________15.3______________ 166.8

V1 ALTA ___________720.2_____________ 54.5%________________6.6_____________________ 9.8______________ 171.9

Flow Through

This test was on our 04 shop car. It had stock ECU programming (obvious by the redline), 15% pulley, ALTA intake, ALTA header, ALTA 2.5" Catback exhaust. If we had a way to raise the redline a bit, then further gains will be seen. The IC we used here was one with the cast tanks, and 12/12fpi.

So when we gave Matt our IC€™s to test, we gave him our normal Classic intercooler, and our V1 ALTA flow through. Its important to note a few things with the ALTA V1 flow through. The tanks were made using parts of our old IC and some sheetmetal. The core was our first prototype core that was a 12.5"L x 2.9"H x 8"D core using 12 fins per inch (very important to note) on both hot and cold sides. This was our first attempt at the core, and Matt was the first to get it and the first to use it!

Here is the data in rough form from Matt. There is tons more data, but his is enough for you all to see.

Intercooler_____ Average Peak Mass_____ Ave IC efficiency_____ Average Cells with Knock_____Pressure Delta_____ Average Peak HP

Stock _____________714.1_____________ 64.2%_________________7.3 _____________________12.7_____________ 166.4

ALTA TMIC_________708.1______________61.0%________________5.4_____________________15.3______________ 166.8

V1 ALTA ___________720.2_____________ 54.5%________________6.6_____________________ 9.8______________ 171.9

Flow Through

Going into this we knew that our classic IC made power on the dyno, and it did it buy cooler really well. The cooler charge temps allowed the ECU to increase timing a bit and added some power. We had many guys with temp probes in the IC give us feedback in lots of conditions. All showing great IC efficiency.

For SEMA of 2005, we came up with the Twurbo kit and wanted to make a bigger intercooler for it. The idea we came up with was what you see. And was something we made very public a few years back. Going into this new core, we knew it would cool worse, but be much less restrictive. But how much worse at cooling and how much power would be made from it being less restrictive. As we have explained before, when designing an IC (using a given space) intercoolers can become a trade off.

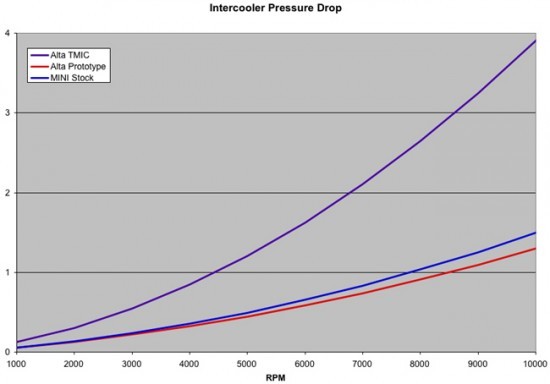

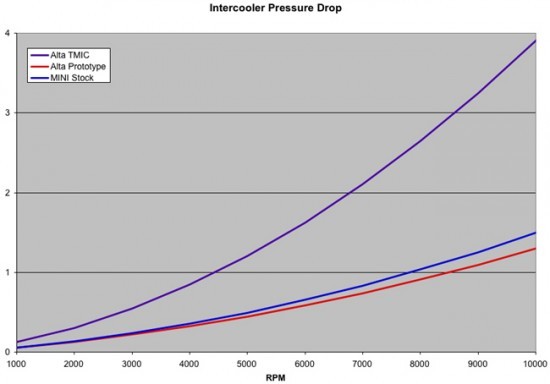

From this data we saw exactly what we expected. It cooled worse but was less restrictive. But it made more HP. Now lets go over the data.

The stock core is our base, and from there we will measure others.

1. The V1 flow through showed the highest Mass readings. Meaning it had the highest air flow, which in turn can means more HP. The classic showed less airflow, which could mean less HP than stock, but there are other variables that play into that, like temp.

2. The Classic IC showed the least amount of knock which makes sense as it has a good balance of cooling and flow. This is why it does make HP on the dyno.

After we got this data we went to our core manufacturer and had them plop the V1 flow-through core into the big special program they have. Actually we were surprised that the temps were almost exactly what we saw in real life.

Design Point: ALTA V1 core 12fpi/12fpi

________________Cold Side ______Hot Side

Fluid ________________Air _________Air

Flow Rate _________225 CFM _____25.72 lb/min

Temperature In______ 60.8F ______216.1F

Temperature Out _____160.5F_____ 149.6F

Pressure Drop _______2.4 "H2O____ .7 psid

Design Pressure _____50 psig ______50 psig

Flow Arrangement ______Cross Flow

Heat Rejection _______412.2Btu/min (7.4 kW)

There is other info we hold secret with the above data, but you get the point. With further tweaking of overall size, and fin type and count, we got and pretty good improvement in overall performance. BTW the effectiveness is not the same as efficiency as it take into consideration a lot more than just temp in and out and ambient. So with that said below is the data with the changes to the core. We lowered the ambient fin count, and added charge side fins. This allowed the ambient air to move through the core quicker and get rid of more heat. The added fins to the charge side means more surface area for the hot charge air to dissipate heat to the cold side of the car.

Design Point: ALTA V2 core 10fpi/14fpi

_____________________Cold Side ___Hot Side

Fluid__________________ Air ________Air

Flow Rate ___________250 CFM ______25.72 lb/min

Temperature In _______60.8F________ 216.1F

Temperature Out ______153.1F_______ 147.8F

Pressure Drop ________2.4 "H2O______ .8 psid

Design Pressure______ 50 psig_______ 50 psig

Flow Arrangement_______ Cross Flow

Heat Rejection _______423.7 Btu/min (7.4 kW)

With our initial findings of the flow though IC making power by being less restrictive and not cooling better, we went with option 2. Things to note on the second option is the CFM. The CFM through the ambient part of the core went up on the V2 core, which is why the Btu/min went up. The more heat it gets rid of the cooler the charge! And we felt that .1psi more pressure drop was perfectly expectable since this will not effect power quite as much as a cooler charge temp is.

So on the dyno, what did we see? The same basic power gains as we had above. At least not definitive enough to make a new graph. But with slightly cooler charge temps and no change in pressure (again not enough to really say we saw a .1psi change) we were happy! Again, this is with our dyno fan which doesn€™t flow like it could when you get above 60MPH.

With that said we feel very confident in our power we got, we feel like we have represented our IC truthfully from day one. The simple truth is it works! Now we haven€™t tested it back to back on our GP, or with a GP intercooler, but we will soon. On that note, our Classic IC is also going through some revisions and as that progresses we will fill you on on that!

Going into this we knew that our classic IC made power on the dyno, and it did it buy cooler really well. The cooler charge temps allowed the ECU to increase timing a bit and added some power. We had many guys with temp probes in the IC give us feedback in lots of conditions. All showing great IC efficiency.

For SEMA of 2005, we came up with the Twurbo kit and wanted to make a bigger intercooler for it. The idea we came up with was what you see. And was something we made very public a few years back. Going into this new core, we knew it would cool worse, but be much less restrictive. But how much worse at cooling and how much power would be made from it being less restrictive. As we have explained before, when designing an IC (using a given space) intercoolers can become a trade off.

From this data we saw exactly what we expected. It cooled worse but was less restrictive. But it made more HP. Now lets go over the data.

The stock core is our base, and from there we will measure others.

1. The V1 flow through showed the highest Mass readings. Meaning it had the highest air flow, which in turn can means more HP. The classic showed less airflow, which could mean less HP than stock, but there are other variables that play into that, like temp.

2. The Classic IC showed the least amount of knock which makes sense as it has a good balance of cooling and flow. This is why it does make HP on the dyno.

After we got this data we went to our core manufacturer and had them plop the V1 flow-through core into the big special program they have. Actually we were surprised that the temps were almost exactly what we saw in real life.

Design Point: ALTA V1 core 12fpi/12fpi

________________Cold Side ______Hot Side

Fluid ________________Air _________Air

Flow Rate _________225 CFM _____25.72 lb/min

Temperature In______ 60.8F ______216.1F

Temperature Out _____160.5F_____ 149.6F

Pressure Drop _______2.4 "H2O____ .7 psid

Design Pressure _____50 psig ______50 psig

Flow Arrangement ______Cross Flow

Heat Rejection _______412.2Btu/min (7.4 kW)

There is other info we hold secret with the above data, but you get the point. With further tweaking of overall size, and fin type and count, we got and pretty good improvement in overall performance. BTW the effectiveness is not the same as efficiency as it take into consideration a lot more than just temp in and out and ambient. So with that said below is the data with the changes to the core. We lowered the ambient fin count, and added charge side fins. This allowed the ambient air to move through the core quicker and get rid of more heat. The added fins to the charge side means more surface area for the hot charge air to dissipate heat to the cold side of the car.

Design Point: ALTA V2 core 10fpi/14fpi

_____________________Cold Side ___Hot Side

Fluid__________________ Air ________Air

Flow Rate ___________250 CFM ______25.72 lb/min

Temperature In _______60.8F________ 216.1F

Temperature Out ______153.1F_______ 147.8F

Pressure Drop ________2.4 "H2O______ .8 psid

Design Pressure______ 50 psig_______ 50 psig

Flow Arrangement_______ Cross Flow

Heat Rejection _______423.7 Btu/min (7.4 kW)

With our initial findings of the flow though IC making power by being less restrictive and not cooling better, we went with option 2. Things to note on the second option is the CFM. The CFM through the ambient part of the core went up on the V2 core, which is why the Btu/min went up. The more heat it gets rid of the cooler the charge! And we felt that .1psi more pressure drop was perfectly expectable since this will not effect power quite as much as a cooler charge temp is.

So on the dyno, what did we see? The same basic power gains as we had above. At least not definitive enough to make a new graph. But with slightly cooler charge temps and no change in pressure (again not enough to really say we saw a .1psi change) we were happy! Again, this is with our dyno fan which doesn€™t flow like it could when you get above 60MPH.

With that said we feel very confident in our power we got, we feel like we have represented our IC truthfully from day one. The simple truth is it works! Now we haven€™t tested it back to back on our GP, or with a GP intercooler, but we will soon. On that note, our Classic IC is also going through some revisions and as that progresses we will fill you on on that!

This is a pic of the scoop modded to fit our interecooler. As you can see it opens it up a huge amount. You still can't see how it opens it up from the other angle. Imagine having one of the Larger M7 scoops on it!

This is a pic of the scoop modded to fit our interecooler. As you can see it opens it up a huge amount. You still can't see how it opens it up from the other angle. Imagine having one of the Larger M7 scoops on it!

This test was on our 04 shop car. It had stock ECU programming (obvious by the redline), 15% pulley, ALTA intake, ALTA header, ALTA 2.5" Catback exhaust. If we had a way to raise the redline a bit, then further gains will be seen. The IC we used here was one with the cast tanks, and 12/12fpi.

So when we gave Matt our IC€™s to test, we gave him our normal Classic intercooler, and our V1 ALTA flow through. Its important to note a few things with the ALTA V1 flow through. The tanks were made using parts of our old IC and some sheetmetal. The core was our first prototype core that was a 12.5"L x 2.9"H x 8"D core using 12 fins per inch (very important to note) on both hot and cold sides. This was our first attempt at the core, and Matt was the first to get it and the first to use it!

Here is the data in rough form from Matt. There is tons more data, but his is enough for you all to see.

Intercooler_____ Average Peak Mass_____ Ave IC efficiency_____ Average Cells with Knock_____Pressure Delta_____ Average Peak HP

Stock _____________714.1_____________ 64.2%_________________7.3 _____________________12.7_____________ 166.4

ALTA TMIC_________708.1______________61.0%________________5.4_____________________15.3______________ 166.8

V1 ALTA ___________720.2_____________ 54.5%________________6.6_____________________ 9.8______________ 171.9

Flow Through

This test was on our 04 shop car. It had stock ECU programming (obvious by the redline), 15% pulley, ALTA intake, ALTA header, ALTA 2.5" Catback exhaust. If we had a way to raise the redline a bit, then further gains will be seen. The IC we used here was one with the cast tanks, and 12/12fpi.

So when we gave Matt our IC€™s to test, we gave him our normal Classic intercooler, and our V1 ALTA flow through. Its important to note a few things with the ALTA V1 flow through. The tanks were made using parts of our old IC and some sheetmetal. The core was our first prototype core that was a 12.5"L x 2.9"H x 8"D core using 12 fins per inch (very important to note) on both hot and cold sides. This was our first attempt at the core, and Matt was the first to get it and the first to use it!

Here is the data in rough form from Matt. There is tons more data, but his is enough for you all to see.

Intercooler_____ Average Peak Mass_____ Ave IC efficiency_____ Average Cells with Knock_____Pressure Delta_____ Average Peak HP

Stock _____________714.1_____________ 64.2%_________________7.3 _____________________12.7_____________ 166.4

ALTA TMIC_________708.1______________61.0%________________5.4_____________________15.3______________ 166.8

V1 ALTA ___________720.2_____________ 54.5%________________6.6_____________________ 9.8______________ 171.9

Flow Through

Going into this we knew that our classic IC made power on the dyno, and it did it buy cooler really well. The cooler charge temps allowed the ECU to increase timing a bit and added some power. We had many guys with temp probes in the IC give us feedback in lots of conditions. All showing great IC efficiency.

For SEMA of 2005, we came up with the Twurbo kit and wanted to make a bigger intercooler for it. The idea we came up with was what you see. And was something we made very public a few years back. Going into this new core, we knew it would cool worse, but be much less restrictive. But how much worse at cooling and how much power would be made from it being less restrictive. As we have explained before, when designing an IC (using a given space) intercoolers can become a trade off.

From this data we saw exactly what we expected. It cooled worse but was less restrictive. But it made more HP. Now lets go over the data.

The stock core is our base, and from there we will measure others.

1. The V1 flow through showed the highest Mass readings. Meaning it had the highest air flow, which in turn can means more HP. The classic showed less airflow, which could mean less HP than stock, but there are other variables that play into that, like temp.

2. The Classic IC showed the least amount of knock which makes sense as it has a good balance of cooling and flow. This is why it does make HP on the dyno.

After we got this data we went to our core manufacturer and had them plop the V1 flow-through core into the big special program they have. Actually we were surprised that the temps were almost exactly what we saw in real life.

Design Point: ALTA V1 core 12fpi/12fpi

________________Cold Side ______Hot Side

Fluid ________________Air _________Air

Flow Rate _________225 CFM _____25.72 lb/min

Temperature In______ 60.8F ______216.1F

Temperature Out _____160.5F_____ 149.6F

Pressure Drop _______2.4 "H2O____ .7 psid

Design Pressure _____50 psig ______50 psig

Flow Arrangement ______Cross Flow

Heat Rejection _______412.2Btu/min (7.4 kW)

There is other info we hold secret with the above data, but you get the point. With further tweaking of overall size, and fin type and count, we got and pretty good improvement in overall performance. BTW the effectiveness is not the same as efficiency as it take into consideration a lot more than just temp in and out and ambient. So with that said below is the data with the changes to the core. We lowered the ambient fin count, and added charge side fins. This allowed the ambient air to move through the core quicker and get rid of more heat. The added fins to the charge side means more surface area for the hot charge air to dissipate heat to the cold side of the car.

Design Point: ALTA V2 core 10fpi/14fpi

_____________________Cold Side ___Hot Side

Fluid__________________ Air ________Air

Flow Rate ___________250 CFM ______25.72 lb/min

Temperature In _______60.8F________ 216.1F

Temperature Out ______153.1F_______ 147.8F

Pressure Drop ________2.4 "H2O______ .8 psid

Design Pressure______ 50 psig_______ 50 psig

Flow Arrangement_______ Cross Flow

Heat Rejection _______423.7 Btu/min (7.4 kW)

With our initial findings of the flow though IC making power by being less restrictive and not cooling better, we went with option 2. Things to note on the second option is the CFM. The CFM through the ambient part of the core went up on the V2 core, which is why the Btu/min went up. The more heat it gets rid of the cooler the charge! And we felt that .1psi more pressure drop was perfectly expectable since this will not effect power quite as much as a cooler charge temp is.

So on the dyno, what did we see? The same basic power gains as we had above. At least not definitive enough to make a new graph. But with slightly cooler charge temps and no change in pressure (again not enough to really say we saw a .1psi change) we were happy! Again, this is with our dyno fan which doesn€™t flow like it could when you get above 60MPH.

With that said we feel very confident in our power we got, we feel like we have represented our IC truthfully from day one. The simple truth is it works! Now we haven€™t tested it back to back on our GP, or with a GP intercooler, but we will soon. On that note, our Classic IC is also going through some revisions and as that progresses we will fill you on on that!

Going into this we knew that our classic IC made power on the dyno, and it did it buy cooler really well. The cooler charge temps allowed the ECU to increase timing a bit and added some power. We had many guys with temp probes in the IC give us feedback in lots of conditions. All showing great IC efficiency.

For SEMA of 2005, we came up with the Twurbo kit and wanted to make a bigger intercooler for it. The idea we came up with was what you see. And was something we made very public a few years back. Going into this new core, we knew it would cool worse, but be much less restrictive. But how much worse at cooling and how much power would be made from it being less restrictive. As we have explained before, when designing an IC (using a given space) intercoolers can become a trade off.

From this data we saw exactly what we expected. It cooled worse but was less restrictive. But it made more HP. Now lets go over the data.

The stock core is our base, and from there we will measure others.

1. The V1 flow through showed the highest Mass readings. Meaning it had the highest air flow, which in turn can means more HP. The classic showed less airflow, which could mean less HP than stock, but there are other variables that play into that, like temp.

2. The Classic IC showed the least amount of knock which makes sense as it has a good balance of cooling and flow. This is why it does make HP on the dyno.

After we got this data we went to our core manufacturer and had them plop the V1 flow-through core into the big special program they have. Actually we were surprised that the temps were almost exactly what we saw in real life.

Design Point: ALTA V1 core 12fpi/12fpi

________________Cold Side ______Hot Side

Fluid ________________Air _________Air

Flow Rate _________225 CFM _____25.72 lb/min

Temperature In______ 60.8F ______216.1F

Temperature Out _____160.5F_____ 149.6F

Pressure Drop _______2.4 "H2O____ .7 psid

Design Pressure _____50 psig ______50 psig

Flow Arrangement ______Cross Flow

Heat Rejection _______412.2Btu/min (7.4 kW)

There is other info we hold secret with the above data, but you get the point. With further tweaking of overall size, and fin type and count, we got and pretty good improvement in overall performance. BTW the effectiveness is not the same as efficiency as it take into consideration a lot more than just temp in and out and ambient. So with that said below is the data with the changes to the core. We lowered the ambient fin count, and added charge side fins. This allowed the ambient air to move through the core quicker and get rid of more heat. The added fins to the charge side means more surface area for the hot charge air to dissipate heat to the cold side of the car.

Design Point: ALTA V2 core 10fpi/14fpi

_____________________Cold Side ___Hot Side

Fluid__________________ Air ________Air

Flow Rate ___________250 CFM ______25.72 lb/min

Temperature In _______60.8F________ 216.1F

Temperature Out ______153.1F_______ 147.8F

Pressure Drop ________2.4 "H2O______ .8 psid

Design Pressure______ 50 psig_______ 50 psig

Flow Arrangement_______ Cross Flow

Heat Rejection _______423.7 Btu/min (7.4 kW)

With our initial findings of the flow though IC making power by being less restrictive and not cooling better, we went with option 2. Things to note on the second option is the CFM. The CFM through the ambient part of the core went up on the V2 core, which is why the Btu/min went up. The more heat it gets rid of the cooler the charge! And we felt that .1psi more pressure drop was perfectly expectable since this will not effect power quite as much as a cooler charge temp is.

So on the dyno, what did we see? The same basic power gains as we had above. At least not definitive enough to make a new graph. But with slightly cooler charge temps and no change in pressure (again not enough to really say we saw a .1psi change) we were happy! Again, this is with our dyno fan which doesn€™t flow like it could when you get above 60MPH.

With that said we feel very confident in our power we got, we feel like we have represented our IC truthfully from day one. The simple truth is it works! Now we haven€™t tested it back to back on our GP, or with a GP intercooler, but we will soon. On that note, our Classic IC is also going through some revisions and as that progresses we will fill you on on that!

This is a pic of the scoop modded to fit our interecooler. As you can see it opens it up a huge amount. You still can't see how it opens it up from the other angle. Imagine having one of the Larger M7 scoops on it!

This is a pic of the scoop modded to fit our interecooler. As you can see it opens it up a huge amount. You still can't see how it opens it up from the other angle. Imagine having one of the Larger M7 scoops on it!