Category : Dyno Test & Tune

Back to Blog

Share This

Evolution of the ALTA R56 Intercooler

ALTA was the first to bring you a larger front mounted intercooler for your R56 and JCW, we were the first to bring you proven dyno performance, we were the first to being you solid temperature data, and the first R56 to break the 280WHP mark with our intercooler, proving our intercooler works for all levels of cars. In the rest of this article you will read about how we came up with our design and our testing/dyno proving along the way.OEM Construction

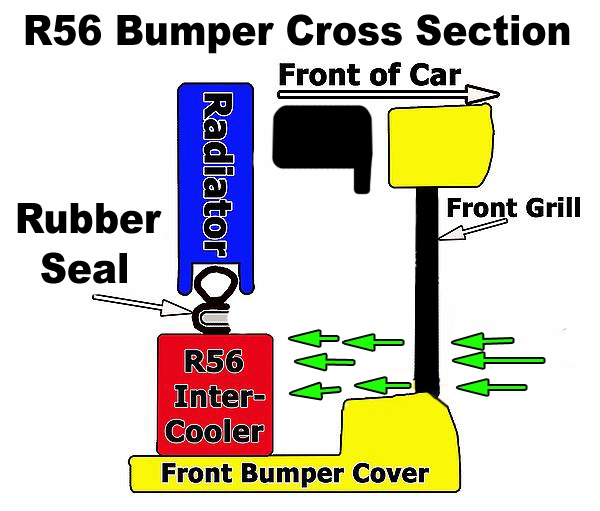

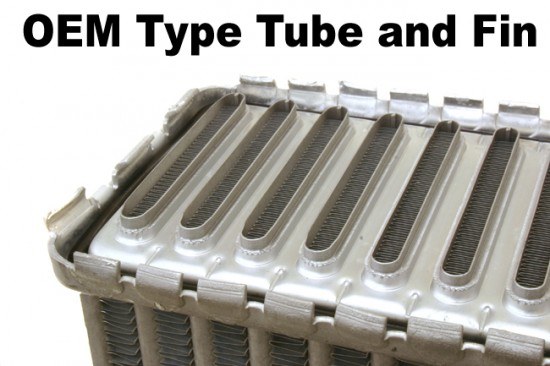

When we first picked up our R56 we were very excited to see how small and crappy the OEM intercooler was. Like most low HP turbocharged cars it came with an intercooler that just barely does the job. We knew that the R56 would be a great tuner car and that this OEM intercooler would be a huge hold up so we had to make a bigger and better one! There are few flaws the OEM intercooler has. It's really small, about 40% of the intercooler is blocked by the bumper from ambient airflow and lastly is it's tube and fin type core. We knew we could make a better intercooler as the flaws were easy to fix and Mini gave us a huge bumper opening to fill! You can see in this cross section of the front of the R56, how the bottom half of the intercooler is not getting direct airflow. While this does an OK job on a stock R56 or JCW, its not good enough for any performance oriented Mini. The OEM intercooler is a tube and fin type of core. This is typical of all OEM type intercoolers because this method is faster and cheaper to make. In this example you can see the tubes and how they stick up. You can also see how small the tubes are and the very dense fins. This creates a very restrictive core that does an ok job of cooling.

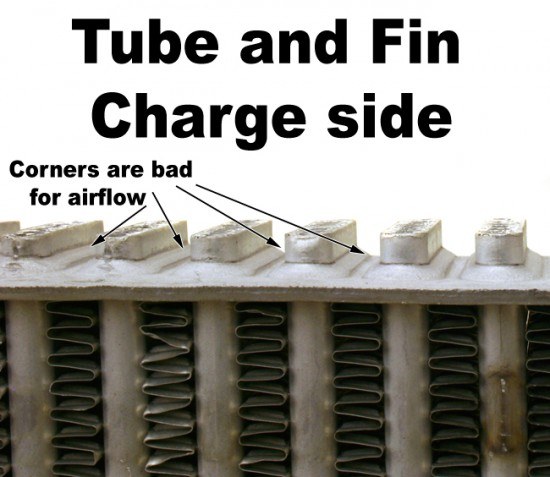

The OEM intercooler is a tube and fin type of core. This is typical of all OEM type intercoolers because this method is faster and cheaper to make. In this example you can see the tubes and how they stick up. You can also see how small the tubes are and the very dense fins. This creates a very restrictive core that does an ok job of cooling.

ALTA FMIC Construction

When designing intercoolers there are many important things to consider, pressure drop (the loss of boost through the intercooler), and how well the intercooler cools the air. For a given size of intercooler, these two are generally a balancing act making one that cools better versus flows more. Another thing is make it as big as possible. As a starting point the bigger it is the better chance you have in making a core that cools better has less pressure drop. Contrary to what forum followers say, bigger isn't what causes a pressure drop, its cross section and fin counts, but that is a whole other story. Using this simple rule of make it big, and with what we know about the ECU and how it deals with air temps, we leaned toward the cooling side of things rather that outright flow. After playing with a couple of fatter, shorter designs (similar to the OEM but deeper) we found we could make a bigger intercooler by going thinner! Seeing that Mini gave us this great big opening in the bumper to fill, we did just that. In order to do this we made a minor compromise requiring some trimming of the plastic behind the bumper. This allowed us to make the intercooler wider by almost 3 inches, which would perfectly fill the bumper opening. Using this initial design we found our older R53 intercooler cores were pretty close! So we stuck a couple together and BAM! we had an intercooler to test out! (if you want to see a picture of this, check out the top picture here. Its ugly but it worked!)

Intercooler Types

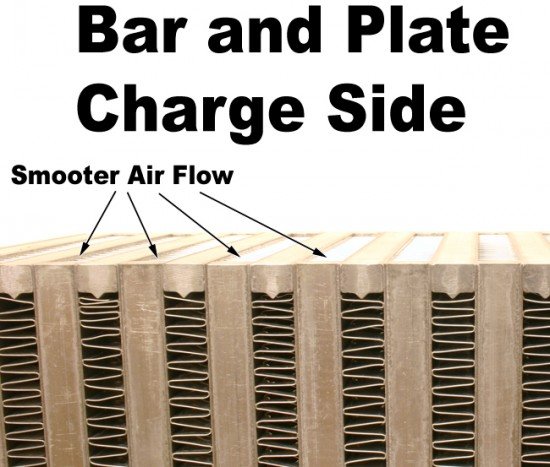

This prototype and final design core uses the same basic type of core known as bar and plate. There are 2 main types of cores, Bar and Plate, and Tube and Fin(OEM Type). While both do very similar jobs, they are very different cores. Bar and Plate cores are constructed using thin plates, and aluminum bars (extrusions) with fins placed in between all the parts. Its basically a big sandwich of plates, fins and bars. The thickness of each layer, and the density of fins can be changed to create the optimum pressure drop and cooling ability. These are then baked in a vacuum, which brazes all the parts together, creating an intercooler core! While there are more parts, and more labor involved with building this type of core, they produce the best flowing and most solid type of core. In this close up shot you can see how smoother and flatter the bar and plate charge side is. This makes for smoother airflow through the core. You can also see the construction of the core and all its pieces that go into making it. To compare this core consists of 90 parts where a tube and fin of the same has 31. Tube and Fin cores are limited to their charge side thickness due to their construction. They are constructed using thin plates, and thin extruded tubes. Between each of these tubes, fins are placed and brazed together in an oven. The picture below shows the difference in cores. The downside is the charge side of the core cannot be as wide as a bar and plate, creating a smaller cross section for air to the charge air to pass through. They also are not very strong against rocks and debris because the tubes are very thin. Their only benefit is they are light weight.

This clearly shows one of the largest flaws, the charge tube sticking out of the header plate. The tubes sticking up create a large nasty corner that is not good for airflow. To make up for this, the charge tubes have to be very open, which then sacrifices its cooling effects.

Tube and Fin cores are limited to their charge side thickness due to their construction. They are constructed using thin plates, and thin extruded tubes. Between each of these tubes, fins are placed and brazed together in an oven. The picture below shows the difference in cores. The downside is the charge side of the core cannot be as wide as a bar and plate, creating a smaller cross section for air to the charge air to pass through. They also are not very strong against rocks and debris because the tubes are very thin. Their only benefit is they are light weight.

This clearly shows one of the largest flaws, the charge tube sticking out of the header plate. The tubes sticking up create a large nasty corner that is not good for airflow. To make up for this, the charge tubes have to be very open, which then sacrifices its cooling effects.

Here is a clear veiw of 2 of the same size cores, but one bar and plate and the other tube and fin. You can see how they are completely different in almost all aspects.

Here is a clear veiw of 2 of the same size cores, but one bar and plate and the other tube and fin. You can see how they are completely different in almost all aspects.

PROTOTYPE INTERCOOLER TEST

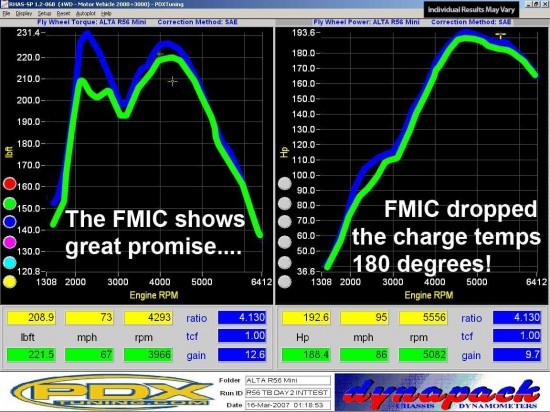

This is the dyno result of the prototype core we made. While being ugly and with some pretty rough endtanks, we were surprised how well it work, and we were looking forward to even better results when we have a proper one done. As shown before with our initial testing (found here in a thread on NAM), the intercooler can make a big difference in power with the stock ECU tuning. Now add your custom ECU tuning, more boost, and maybe even a bigger turbo, and the intercooler becomes a vital part to keeping your engine making safe big power. The below graph shows our initial testing of our prototype intercooler which just a small example of things to come.

This graph shows our more restrictive cobbled together prototype core, we test on a car with only a turboback exhaust installed. While not optimum it created a 5-10 WHP gain and 10-20ft-lbs of torque gain. This made a very noticeable difference in how the car accelerated and also how repeatable the runs were. With a proper built core and cast aluminum entanks we knew there was more to be had.

Our Prototype core showed a huge improvement over the stock core, by dropping the intercooler outlet temps as much as 40 degrees F over the stock intercooler. The prototype core we measured roughly 3PSI of pressure drop across the core, where the stock one was around 2psi. To compare, a typical properly designed core is around 1psi of drop. Pressure drop is always going to be there, but the higher it is the harder the turbo has to work and that makes for a loss in power because the turbo may become less efficient. So 3psi is a lot and you think it would cause a loss in power, but the above proves that the air temp change is part of why it gains power.

As shown before with our initial testing (found here in a thread on NAM), the intercooler can make a big difference in power with the stock ECU tuning. Now add your custom ECU tuning, more boost, and maybe even a bigger turbo, and the intercooler becomes a vital part to keeping your engine making safe big power. The below graph shows our initial testing of our prototype intercooler which just a small example of things to come.

This graph shows our more restrictive cobbled together prototype core, we test on a car with only a turboback exhaust installed. While not optimum it created a 5-10 WHP gain and 10-20ft-lbs of torque gain. This made a very noticeable difference in how the car accelerated and also how repeatable the runs were. With a proper built core and cast aluminum entanks we knew there was more to be had.

Our Prototype core showed a huge improvement over the stock core, by dropping the intercooler outlet temps as much as 40 degrees F over the stock intercooler. The prototype core we measured roughly 3PSI of pressure drop across the core, where the stock one was around 2psi. To compare, a typical properly designed core is around 1psi of drop. Pressure drop is always going to be there, but the higher it is the harder the turbo has to work and that makes for a loss in power because the turbo may become less efficient. So 3psi is a lot and you think it would cause a loss in power, but the above proves that the air temp change is part of why it gains power.

Best Tool in the Shop, the Dynapack Dyno!

We would not be here and be able to provide our customers with hard proof something works. Also because we are not held captive by "renting a dyno" we can do tests over and over again, to make 100% sure the part works. With initial testing done, it was to the drawing board to create the final core design and cast aluminum endtanks. Using special CFD software we were able to design and test a few cores in the virtual world before we even did any realworld testing. Since we don't use off the shelf cores like many companies do, we were able to create an intercooler exactly the way we wanted it by tweaking the fin design, number of fins per inch and how many and the size of rows. This allowed us to quickly make an intercooler with minimal pressure drop and very efficient at cooling the hot air coming out of the turbo. Using CFD software along with our real world testing we were able to deliver the first larger front mounted intercooler for the Mini R56. And to this day the only proven Intercooler for your Mini!

With initial testing done, it was to the drawing board to create the final core design and cast aluminum endtanks. Using special CFD software we were able to design and test a few cores in the virtual world before we even did any realworld testing. Since we don't use off the shelf cores like many companies do, we were able to create an intercooler exactly the way we wanted it by tweaking the fin design, number of fins per inch and how many and the size of rows. This allowed us to quickly make an intercooler with minimal pressure drop and very efficient at cooling the hot air coming out of the turbo. Using CFD software along with our real world testing we were able to deliver the first larger front mounted intercooler for the Mini R56. And to this day the only proven Intercooler for your Mini!

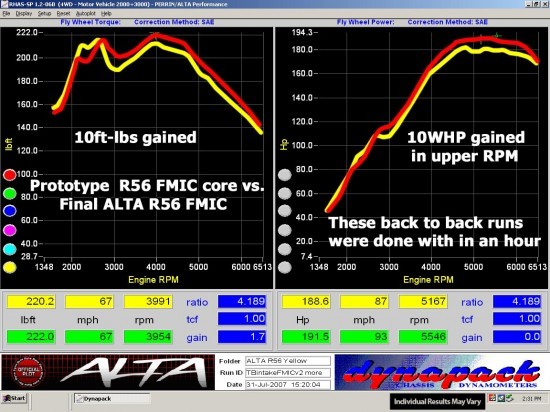

Prototype vs. Final Design

In the below test, we ran the prototype intercooler and final design back to back. Just like we expected to see, even more wheel HP! This test was done on our first R56 which at the time had a turbo back exhaust with 2 cats, and an intake system installed. The ECU programming was stock, so stock boost levels also! Its hard to compare this test to the one done previously with the prototype core as it was done on a completely different time period and much cooler out. Either way, our prototype made more HP than stock, and the production intercooler made more HP than our prototype. Check out the dyno graphs below!

POWER, POWER AND MORE POWER!

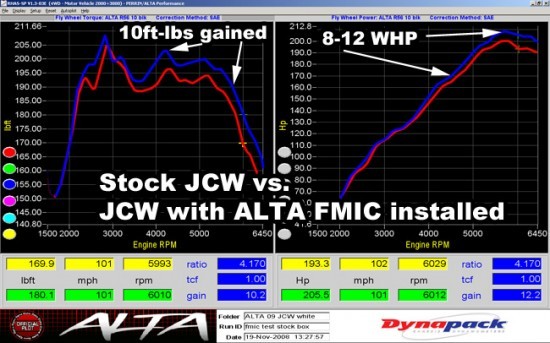

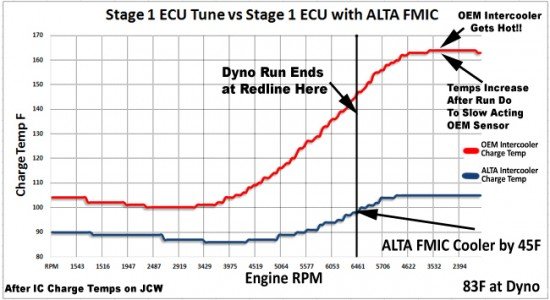

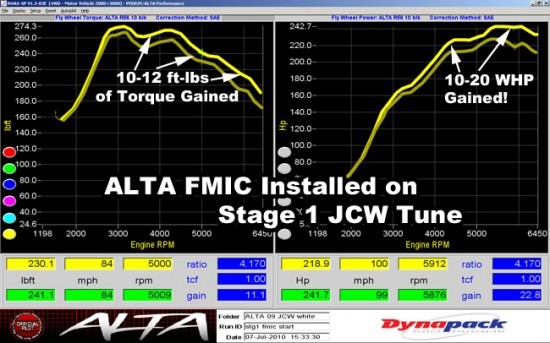

Why does the ALTA intercooler make more power than the stock one?? The biggest one is its cools the air better than the stock intercooler. While pressure drop is a benefit, its not such a huge difference because the turbo can run more boost very efficiently with no detrimental effects. The R56 reacts better to cooler charge temps because cooler charge temps allows for higher boost, and it helps control detonation/knock under heavy loads. The ECU is constantly monitoring the intake manifold temp and when it sees it get too hot it retards ignition timing and reduces overall boost, to help control detonation that can occur. In fact the ECU is very aggressive when the temps get hot, meaning when it hits somewhat normal 140F it's pulling a few degrees of timing killing lots of horsepower. Well not really killing horsepower, but keeping your engine in a safer state. Our intercooler does such a good job at cooling the air off that you will NEVER see these high temps that will cause your ECU to retard ignition timing. This is the biggest reason why the ALTA FMIC makes power on a stock tuned ECU car. But if you are able to tune the ECU there is many other benefits as the ALTA FMIC will allow you to hit much higher boost targets and hit them safely. On tuned ECU cars we see 20WHP gains all the time! Below are some results we saw on a Stock JCW Stage1. This means no aftermarket parts installed, but only an ECU retune. We would see air temps climb up to 150-155F at redline while on the dyno with the stock intercooler. After the run was over the temps would continue to climb up reaching 166F! This happens because of the slow acting nature of the temp sensor. With the ALTA intercooler installed, we would see peak temps hit 98F!45-55F COOLER CHARGE TEMPS!

The ALTA FMIC cooled the charge temps 45F-55F cooler than the stock FMIC. Unlike our competion, we tested this on the same day on our dyno within 1 hour of one another. These tests were done on a Stage 1 JCW (Stock car with an ECU tune) and what you can't see is how repeatable these numbers are!

10-20 WHEEL HORSEPOWER GAINS ON STAGE 1 JCW

These are dyno numbers backing up the above temp graph. The car is the same Stage 1 JCW, with nothing done but the ALTA Intercooler between runs. The 10-20WHP and 10-12 Ft-lbs of torque are great gains! Below are some results we saw on a Stage 2 JCW. This means a turboback exhaust and ECU tune were done. We would see air temps climb even higher to 160-170F with the stock intercooler. The temps were higher because we were running more boost. After the run was over the temps would continue to climb up reaching 185F! This happens because of the slow acting nature of the temp sensor. With the ALTA intercooler installed, we would see peak temps hit 101F!

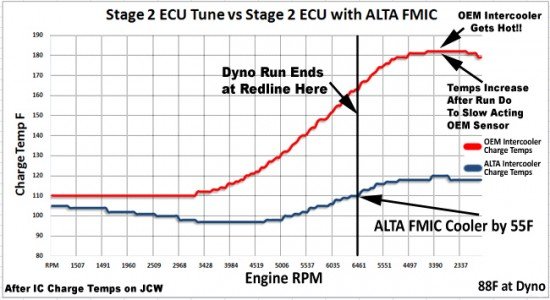

Below are some results we saw on a Stage 2 JCW. This means a turboback exhaust and ECU tune were done. We would see air temps climb even higher to 160-170F with the stock intercooler. The temps were higher because we were running more boost. After the run was over the temps would continue to climb up reaching 185F! This happens because of the slow acting nature of the temp sensor. With the ALTA intercooler installed, we would see peak temps hit 101F!

55F-65F COOLER CHARGE TEMPS!

Here is another test done on the same car as above but in Stage 2 form. Stage 2 is when a turboback exhaust is installed along with a proper ECU tune. Nothing was done between the runs except changing the intercooler to an ALTA FMIC.

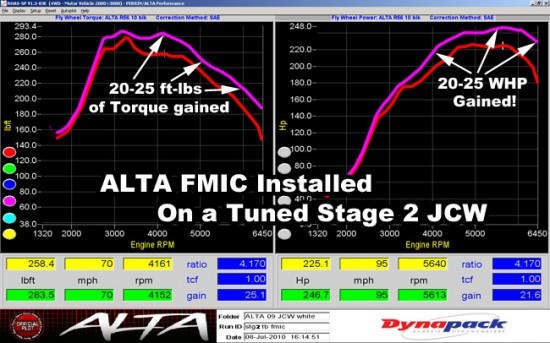

20-25 WHEEL HORSEPOWER GAINS ON STAGE 3 JCW

Any JCW would love to have power like this! The ALTA FMIC is key to making consistent big power! We see similar overall gains on R56's in stage 2 form. This is the dyno graph that goes along with the temp data above. These are proven back to back runs done on a dyno where its consistent run to run. Others try selling you that their intercooler is tested back to back on the road, but really its done days and days apart with different ambient temps, different roads, and who knows how many other variables. Our tests are done with consistent flowing fans, providing constant airflow. While these don't provide quite the same air flow as you would see on the track, the numbers we show are repeatable over and over again, and on the street you will see even better results.

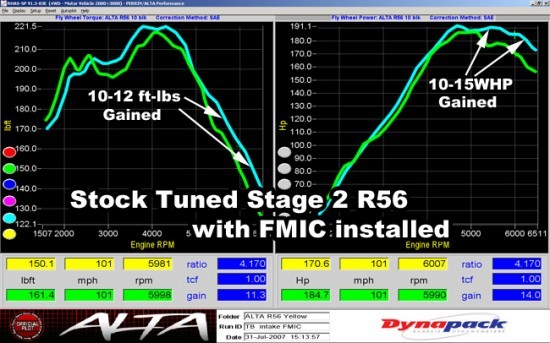

Below are a few more examples of gains you can expect.

These are proven back to back runs done on a dyno where its consistent run to run. Others try selling you that their intercooler is tested back to back on the road, but really its done days and days apart with different ambient temps, different roads, and who knows how many other variables. Our tests are done with consistent flowing fans, providing constant airflow. While these don't provide quite the same air flow as you would see on the track, the numbers we show are repeatable over and over again, and on the street you will see even better results.

Below are a few more examples of gains you can expect.

10-15 WHEEL HP GAINS ON STAGE 2 R56

This is what you can expect for wheel horsepower gains on an R56 with only a turboback exhaust installed and stock ECU tuning.

8-12 WHEEL HP GAINS ON STOCK JCW

This is what you can expect for wheel horsepower gains on an R56 with only a turboback exhaust installed and stock ECU tuning.HOW DOES THE COMPETITION STACK UP

The competition touts a 20F temp drop over the stock intercooler, when we see 50-60F temp drop with ours! This is the biggest reason why our intercooler makes horsepower and to a level that far exceeds other R56 Intercoolers on the market. We achieve these huge temp drops and HP levels by making the intercooler fill the front of you bumper opening completely. This translates into a surface area that is 2.9 times larger than the stock intercooler! The internal volume of the ALTA Intercooler is much larger (2 times larger) than stock allowing the intercooler to cool better and flow even more air! The competition sells theirs as being only 50% larger volume and ambient surface area. Our "Equal" flow intercooler distributes the super heated charge across the entire face of the intercooler ensuring all of the charge gets cooled equally and completely. Air will flow through the path of least resistance and on these stepped type cores, the fatter lower portion has much less pressure drop than the upper thinner part. So most of the air is flowing through the lower area, where its blocked partially by the bumper.. The thinner area is where the best cooling is going to happen but this is where the least amount of air is going to go. This is where our intercooler shines and the whole thing is built equally making sure all the air is cooled the same! While looks shouldn't be the first reason to buy an ALTA intercooler our intercooler fills the whole grill and is centered in the mouth giving it the best chance to cool off the charged air. You can feel proud to remove the lower grill and really show it off! Our completion sacrifices functionality for installation reasons making the intercooler narrower like the stock intercooler. What most people don't notice is that this also makes the intercooler offset to one side by about 3 inches. This is done to save some installation time.Uses all of Bumper Opening

Our intercooler is designed to be as big as possible and utilize as much of the ambient air coming through the bumper as possible. You can see our intercooler fills the whole mouth of the bumper. With the grill installed you can see its still visible!

NO COMPROMISES

Installation of any intercooler requires the same basic steps, but the ALTA intercooler requires one additional step to install. We require some removal of plastic which takes about 20 extra minutes to do for a DIY'er. This is one of those things our competitors say is the biggest downfall to the ALTA. If 20 minutes of time isn't worth the proven HP and temp changes, and a symmetrical fitting intercooler, then don't change your intercooler.Conclusion

The ALTA R56 Front Mounted Intercooler goes hand and hand with other performance upgrades on your Mini Cooper S R56. With the results we have seen over the years, I would argue all day that this is the single best part for your R56 or JCW. With the above proof, i think you will see the ALTA intercooler is the best intercooler out there for your R56 and JCW!