Share This

Everyone has an air filter on their engine (at least you should!) and this goes true for all types of things that that suck in air constantly. Yes even you have a filter; your nose has them built into it as does your air passageway. But we are talking about your car here which sucks in way more air than you do, so it has much more special filtering needs. Also we are talking about a filter for your performance engine where we care about air flow. If you are reading this article and thinking this is all about high HP engines, there is some good info even grocery getter GEO owner can get from this.

Why do I need a filter? If you like coffee, you need to filter out the grounds so your cup isn't full of the gritty grounds. If you like to breathe clean air in your house, you need a filter on your heating/cooling system. Your engine also likes clean air to keep dirt out of its precise and vital inner workings. With out a filter over thousands of miles, small dirt particles can cause engine wear which leads to loss in performance, efficiency and can lead to engine failure. Imagine sand paper dragging across every little part in your engine eventually wearing down things like piston rings, bearings and causing build up on valves, killing power and efficiency. No one wants that!

A filter needs to filter dirt out of the air, and still allow air to flow into the engine. A filter needs to do this while acting as though it's a big open hole allowing air into the engine (no restriction). So how can you make a big open hole also keep out dirt and debris? Lasers could work, but lasers and the dirt-tracking system might not be cost effective. But really, there are lots of ways to do this simply and cost effective.

Types of Filters

There are lots of types of filters out there. The most common is the OEM style paper filter, simple effective, but not efficient. Oiled Paper is along these same lines, but not very common (GT-R has them), more restrictive but even better filter. Then we get into the aftermarket world and the name K&N comes up. These are also known as gauze filters, and there are tons of versions of this style out there. By far this is the most common type in the aftermarket world. One recent variant of this is a dry version which doesn't use oil like the K&N. One of the more little known types is foam. Foam is the least popular not because it doesn't work, but rather because it's not marketed very well, and K&N has a much bigger budget here. What's funny is the story is quite opposite if you are a motorcycle. In the off road world foam is the winner! One more to mention is the Stainless Steel mesh type. This is a dry type filter consisted of a very tightly woven Stainless Steel mesh. We will hit on all these filters below and give them a fair comparison.

Paper Filters

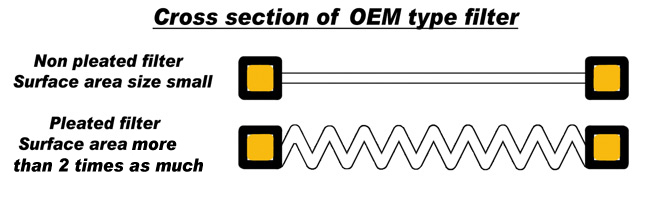

As I said filters have to filter, and flow at the same time. In order for a filter to flow, the microscopic holes have to be open enough or a large enough quantity of them, to allow air to pass through it. In order for it to stop dirt, these holes can't be too big or your filter won't filter very well. OEM's have to balance the size of the filter's microscopic holes and the quantity of them (surface area) to get the most from the filter. Because the OEM's typically use a paper type of construction (inexpensive method of construction), they are limited in a lot of ways. This paper type of filter is the most common type of filter, and isn't too much different than your coffee filter. The only real difference is the way the OEM pleats the filter to gain more surface area. This is an essential part to making a paper filter flow more air as they are restrictive in their nature.

The cross section above (while crude) shows how pleating adds at significantly more surface area to the filter. These paper filters are a single dry layer of material simply blocking dirt bigger than its smallest hole. While good this means in order to block small particles of dirt, it must be restrictive. One last benefit of paper filters is the media is rigid. This keeps the filter from collapsing on it self and eliminates the need for a cage. One large downfall is when the filter gets dirty you throw it away and buy a new one. This not only cost you more money be also creates more waste. Do not try to wash this type or you will quickly discover that the media expands and turns into a block-er not a filt-er. While this is the most common, there are many may more types of filters besides paper.

K&N (AKA Gauze)

The next most common type is the gauze or K&N type. K&N is very well known and they should be as they really are the ones who brought performance air filters to the aftermarket world. Their principle works very similar to a paper filter, but 2 things make it work much different. The media is much more open (significantly bigger holes), and the media is oiled! The filter media is a few layers of very open gauze material. The larger holes/air passages are what make this flow so well. But the bigger holes mean more dirt gets past it, right?? This is where the oil comes into play. The oil creates a sticky layer that as the dirt runs into the media, it gets stuck in it. So instead of blocking dirt it's catching it! Oil on the filter is what really makes this rather "open" filter work.

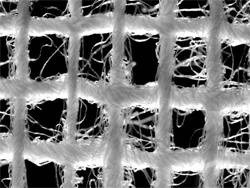

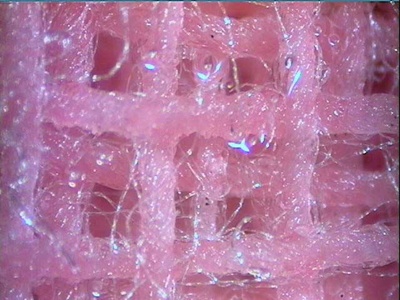

An up close picture of a layer of the gauze material. Left is one layer right is multiple oile layers.

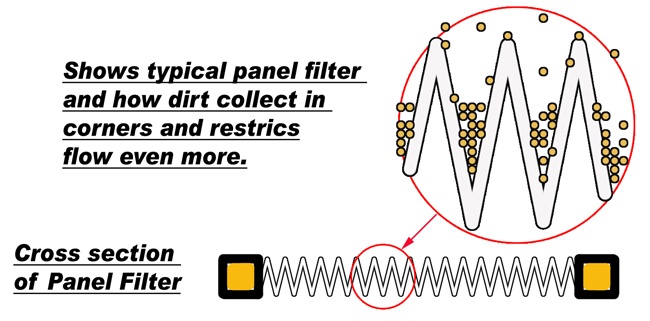

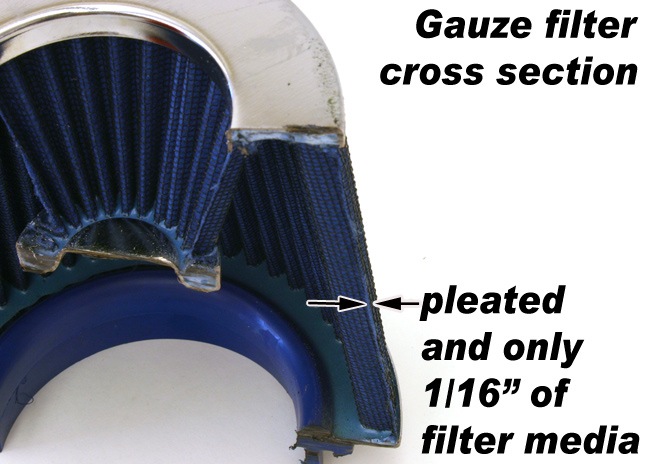

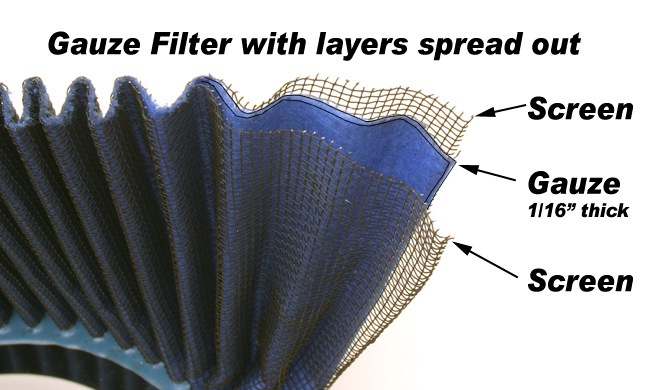

The K&N filters are also pleated to increase its filtering ability and to increase its dirt holding capacity. While this does make it similar to a paper filter, if you look closely you will see a screen on both sides of the filter. This is needed because the gauze material is very flimsy and it needs support. The "cage" provides the support so the media doesn't get sucked into engine and also makes for a durable outer layer to protect against large debris. The diagram below shows a cross section of a gauze filter and you can see the screen on the top and bottom of each layer and the gauze in the middle.

The diagram below shows how dirt typically collects on any type of pleated filter. As dirt tries to pass through it, the dirt collects in the corners. While this doesn't affect the filter from filtering dirt, it makes it very restrictive and doesn't provide a very longer service life before it needs to be cleaned, or thrown away. Go out to your car and grab the OEM filter or the K&N from your intake and you will see this example.

The other revolutionary thing about the K&N filter is its washable! You do not have to throw it away, you just clean it and re-oil it! But you do loose some of the material every time you wash it. It sounds like we are saying the K&N type of filter is the way to go, but hold your horses!

The K&N filter in almost everyway is better than an OEM filter, but if you compare it to other filter types you start to see some major downfalls. K&N filters do have "The Name", the marketing and celebrity endorsements, which is why they are so well known and "seem" to have a superior product............

New World Filter

In the world of aftermarket filters, everything is cleanable. Most use oil as the media the catches the dirt, which then is cleaned and re applied, some are dry type filters and are just washed and dried but either way the aftermarket filters are always reusable in one way or another. So we won't get into that to much as this is a something to expect and something you shouldn't even have to ask of an aftermarket filter manufacturer.

Foam, something you sit on everyday, sleep on at night, and something you find in your morning latte and even in filters?? Foam filters are not something we invented but we are here to educate you why they are the best. To do this we created some diagrams to help you better understand foam filters and how they work compared to the K&N.

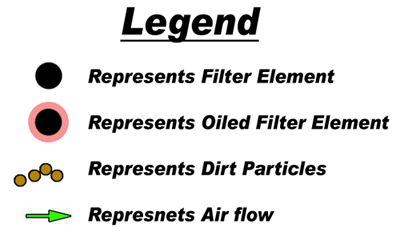

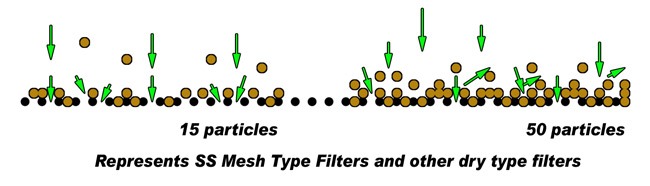

The diagrams should help explain how foam, gauze and dry type filters work. The first thing to understand is filters are filters. They have to stop dirt by either blocking or catching it. Most aftermarket filters catch dirt by using thick oil on the media. This allows for a more open filter element to flow better and still allow for the filter to filter. Some of the dry type filters really block more than catch. The dirt is kept from passing through the filter by very very small openings. Which works fine for filtering, but not for flowing when dirty. All these points have examples below.

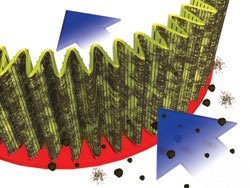

Paper and Dry Filters

First up is a dry type filter which is like an OEM paper type or like the stainless steel mesh type. These are a single layer of filtering media and are a blocking type of filter. Below is an example of 15 and 50 parts of dirt on a single layer of filtering media. The filtering media is much closer together as it needs to block the small dirt particles. The below drawings are to give you an idea of how they work and may not be 100% accurate.

You can see at 50 parts of dirt, its really not a filter anymore. Even at 15 parts its starting to get restrictive. A paper filters relys on one thing to keep functioning, you buying a new one every year! The Stainless Steel mesh type filters rely on you stopping the engine. When you stop the engine and there is no vacuum pulling on the dirt and it SHOULD fall off. But does it?? Does dirt just fall off your car when you stop? If it did I wouldn't need to buy so many micro fiber towels to wash my car. Dry filter companies try to push their product as safe with MAF sensors. Its true they are safe with MAF sensors and don't have a chance to get oil on the precision parts of a MAF sensor. But oil from a foam or gauze filters rarely gets to the MAF. This is true when cleaned properly. More on this later...

Gauze vs. Foam

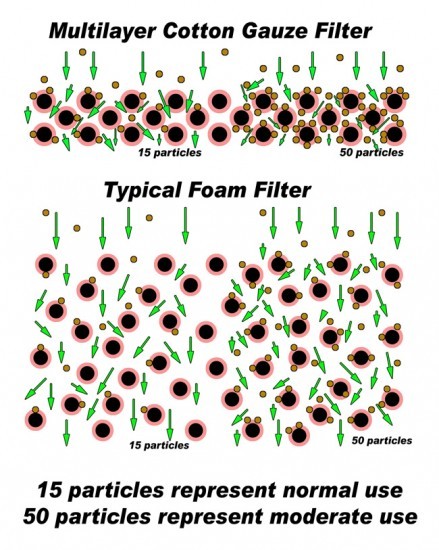

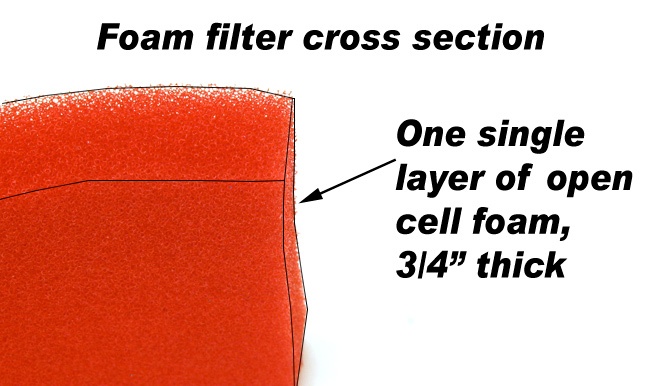

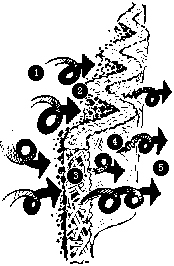

Next up is an example of a cross section of a gauze filter versus a typical foam filter. We say typical because they can be much denser or more open. The gauze filter is constructed of a few layers of gauze (not to much different than your bandages). Again this is a typical version of the filter as there could be more layers than shown or less.

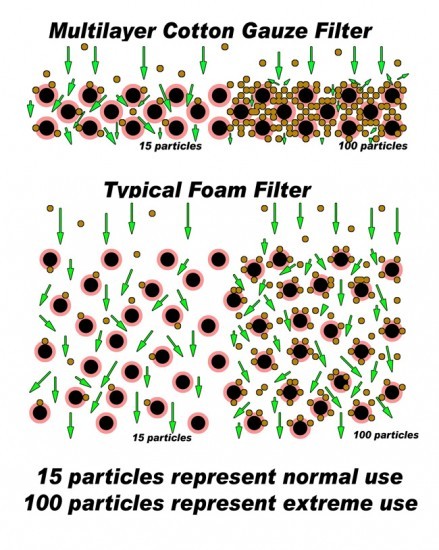

With a low amount of dirt (represented by 15 parts of dirt) flowing through the filter you can see it's very open and still flows air just fine. Start to add more dirt (50 parts of dirt) and you can see how it can clog up. The dirt gets stuck to the oil coated gauze. As far as this goes it's a great filter and it captures dirt just fine. But the more dirt, the less flow. The less flow, the less power!

In this example comparing the gauze type filter with 15 parts of dirt versus the foam with the same 15 parts, you can see how they are both pretty open. But comparing the gauze with 50 parts and the foam with 50 parts you can see how the gauze gets clogged and the foam is still very open. The 50 parts represents what you will see at a normal service interval of 5-10K miles.

The foam has a much larger cross section and also has more places for the dirt to stick to. It also is much more open which is great for flow. The large open cross section is has very random passages through it which means the air can't go straight through it. The dirt also can't go straight through it, which is how the dirt gets "caught" in the filter. The many layers foam has, and the passage the air/dirt has to take is the main reason foam works so well.

The below diagram is an extreme loaded situation where 100 parts of dirt represent a filter with more than 2 years of service. You can see that the gauze is basically clogged and while still filtering dirt the air flow is significantly cut down. But it's not something you will notice as this process is very gradual. What you will notice is that when you clean the filter your car will get better mileage and feel snappier.

In these extreme conditions 100 parts of dirt in a foam filter is nothing! In fact 200 parts in these examples still leaves room for air to pass through. There is a reason why foam has a cleaning period almost 2 times longer than a gauze filter (the period before a loss of performance is felt). Imagine you are a dirt bike and you operate in dusty conditions. Which filter are you going to want? This is kind of extreme but there is reason to why foam filters are found on nearly every single off road vehicle in the world.

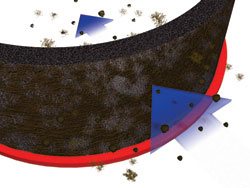

This is an example of how foam collects dirt. In this pic you can see the dirt being trapped through the whole filter, not just the top layer like gauze filters and other dry type filters. This filter is was cut in half with only a few hundred miles on it to show how the dirt gets trapped through out the whole filter.

This is an example done with the typical gauze filter and our foam filter. A single layer of each filter was put on a light table (LED lights) and under each piece is a sticker in the shape of an arrow. You can see how thin the gauze filter is by how much light is let through it. The light represents holes and represents in turn its lack of potential filtering.

Keep I mind these are just basic examples of how filters work and examples to help explain in a somewhat simple way how one is better than another. Yes they may be slightly skewed to favor foam, but there is a reason why we push foam over all other types!

MARKETING BS

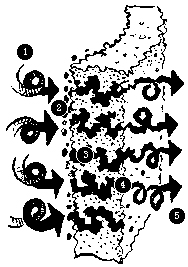

Companies with these dry type or gauze types of filters all show the same thing comparing them to other filters using graphics like this. These kinds of graphics are used to throw you off the trail of the better filter and make theirs look best. This one is trying to sell you on a gauze filter.

Shown above is a stock type filter, foam filter, then a gauze type. Notice how the stock panel filter is depicted at not filtering very well. OEM filters filter very well, which is why they are restrictive. Then notice how the dirt is collecting in the corners of the pleat. This part of the diagram is correct. Then they show a foam filter not filtering which is not typical of how they work. To be fair, a foam filter can be made with varying cells per inch and they could be depicting one made with too few cells per inch, making it very open and not a good filter. Lastly they show a filter of their own where ZERO dirt passes through it which is basically impossible as all filters let some pass through. Then it shows how the dirt collects on all surfaces, not just he cracks. Again, this is not correct. You can see that there is some fudging going on here making one filter look better than another.

Another example showing how OEM filters and Foam filters are bad. The numbered points are not something we have put together, the manufacturer has. These are the drawings and words right off K&N's website.

| Disposable Paper Air Filter | |

|

|

As the dirt builds up it does get more restrictive, this is true on all filters. The need to replace the filter at 10K miles is also true, but so is cleaning your aftermarket filter at 10K. The fibers can swell when blow-by oil touches it, but no modern engine plumbs the crank case vents in front of the filter, so there is no way oil will see it. These points are kind of lame on their part.

| Typical Foam Air Filter | |

|

|

The lack of surface area?? If you could actually measure this, foam would have many many times the surface area of a K&N. Dirt doesn't build up on the outside; it builds up trough the whole filter allowing it to flow when dirty. If higher vacuum pulls more dirt deeper into the foam, then doesn't that give more dirt hold capacity? Airflow is reduced as cells become blocked; this is true, but reduced by how much?? It takes significantly more dirt to "block" a foam filter than a K&N so why would they say this? I know why.......

Another thing these diagrams are showing is how air gets turbulent passing through it. On any filter that has multiple layers (where the dirt can't pass straight through) the air has to make turns before it passes through. This creates turbulence. So, even the K&N type creates turbulent air as it passes through it. The only filter that may not have turbulent air is the SS mesh type, but these are still pleated which leads to turbulent air. In the end this doesn't matter a single bit on a turbo car (I think on any car actually) because the turbo creates a lot more turbulence than any air filter will. This is an over played fault of OEM and foam filters and supposedly non-existent on K&N type filters.

All companies have a section that explains why theirs is the best. The big companies (that think they do not have to sell you on their filters) hide or manipulate this info to throw you off track. It's a good thing because some of this info is contradictive, or if compared to another filter can raise questions.

Another thing you will see is there are lots of tests filter companies have done comparing lots of different filters with air flow tests, dirt holding capacity tests and things like that. But they tend to leave out foam, I wonder why??

HOW DO WE SELL THEM:

HP?? Are you sure??

We sell our filters by saying all filters when new flow about the same. But when dirty, foam continues to flow more air. In an example of an OEM filter being replaced with a PERRIN foam filter (on an STI), we see about a 3 wheel Horse Power gain. This is not much at all and not something you can generally notice. So its not that your stock filter when clean is super restrictive, but throw 10,000 miles at it, and the story changes.

Another feature our filters have is we make them thinner than OEM filters. In many cases this helps with making HP by freeing up area between the air box and filter.

CPI

Our filters have a CPI (cell per inch) spec that we feel is perfectly optimized for both performance and filtering. Some foam filter companies use a very low (meaning very open) CPI, and while these can flow better initially, they do not filter very well. We are talking about Air "filters" here so the filtering aspect is an important one to consider.

Above shows 2 different variations of cells per inch. You can see the top one is more open and the lower one is denser. A perfect balance of open vs. closed is necessary to get performance from the filter as well as good filtering.

Oiled for your protection!

All our foam filters are oiled with special thick, oil that clings to the foams structure. This special oil is what makes our filter, filter! The oil is what stops the dirt from passing through the filter getting into your engine. The oil is what catches the tiny little particles that would normally pass through the open holes in a dry type filters. The only dry type filters you will find around our shop are OEM ones we have thrown away or our foam filters in the middle of being cleaned! Dry filters rely on the very very small openings (as seen in the pics above) to stop dirt. Then they rely on being cleaned very often to get rid of the dirt to keep it flowing freely.

Cleanabilty

Unlike other cleanable cone type filters, our filter is easy to clean, and clean well. Typically when its time to clean your K&N or similar, you have to spray it down with degreaser and hope you got it deep enough to clean through the entire filter. Then when its time to oil it, you have to over oil it to ensure you get oil through the whole thing. If you remember earlier I mentioned how dry filter companies push that their filters don't hurt MAF sensors due to no oil. Over oiling is not good for MAF sensors and this is another reason why our filters are so good.

Our new version filter lets you remove the foam part of the intake separate from the cage. This means you can physically work the degreaser into the entire thickness of the foam to clean out ALL of the dirt. Then when it comes time to oil it, only a small amount of oil is needed as you can work the oil through out the whole filter. This means less oil is used and less chance of over oiling that might affect the MAF sensor. Also it keeps waste to a minimum.

Here is a video we made showing this off.

No rubber here.....

The way our filter is constructed is also different than others in the materials we use. The cage is a zinc plated steel cage to keep the filter media from collapsing on its self. This is very normal for all filters, but where ours differs is in the base. Our base is made of urethane. Urethane is like rubber, but more durable, and more resistant to heat than rubber. Also over time urethane will not deteriorate and crack like rubber. It also has a broader range of operating temps compared to rubber, which means when extremely cold out, it won't get brittle and break.

Panel Filters and Cone Filters

We have shown you how a foam filter is superior in many ways over all other types, its important to understand how it all comes together with an intake system.

Up till now the discussion has revolved around OEM and aftermarket type panel filters which are meant to fit in the OEM intake boxes. The same logic can be applied to cone type filters if you are comparing similar sizes from one another. But keep in mind that with OEM intake systems, these are limited to airflow and filter area based on the size of the filter it starts out as. Meaning if you have an OEM air box that has a 8"x8" filter in it, you can't install a bigger filter, nor can your aftermarket panel filter have more surface area to flow more air. It still can't flow more air than the 8"x8' hole. This concept is important to understand as the big gains in HP from replacing filters isn't had by replacing panel filters with better aftermarket panel filters. In this case the biggest feature is, not having to replace the filter every year.

Big gains can be had when a properly designed intake system that uses a cone type filter is installed. The cone type filter has a huge benefit of sucking air through a nearly infinitely size space. This is an important thing to understand. If a cone filter is sitting in a fender well, the filter has a huge amount of area to suck air from. This allows a larger overall size filter to be used which increases the surface area of the filter for flow and for collecting dirt. If you put this same larger filter a box that an 8"x8" panel filter was in, its still restricted in its flow and cleaning ability as its now crammed into a tiny area. Imagine going out for a run in park then going for a run in a bathroom. Where do you want to go for a run? This is where big HP can be had. When a large cone filter can be used the maximum amount of air can be ingested by the engine. In many cases we have seen ZERO gains in HP when removing a properly sized cone filter from an intake on a turbo car. Foam filter of course!

One thing to keep in mind, with aftermarket intake systems (not just the filter) is cars that use MAF (Mass Air Flow) sensors can be greatly affected by installing a high flow cone filter. These filters can affect the MAF sensors readings and change how the car runs, sometimes it's for the better, sometimes its worse! In these cases keep in mind gains or losses in HP may not be properly realized without retuning of the ECU. Make sure the intake you buy or cone filter you install doesn't affect your HP in a negative way!

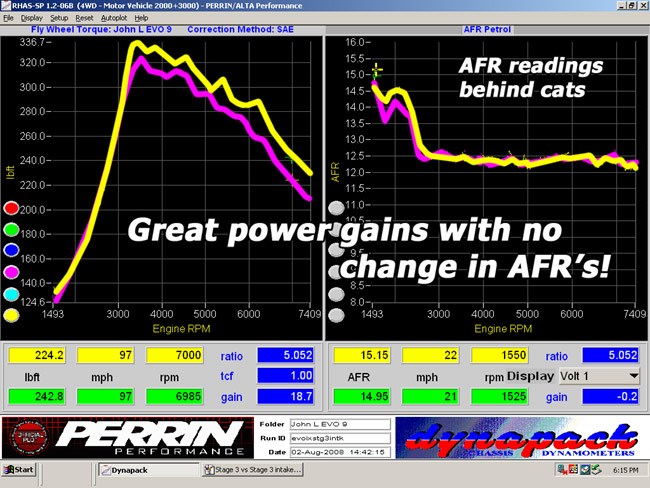

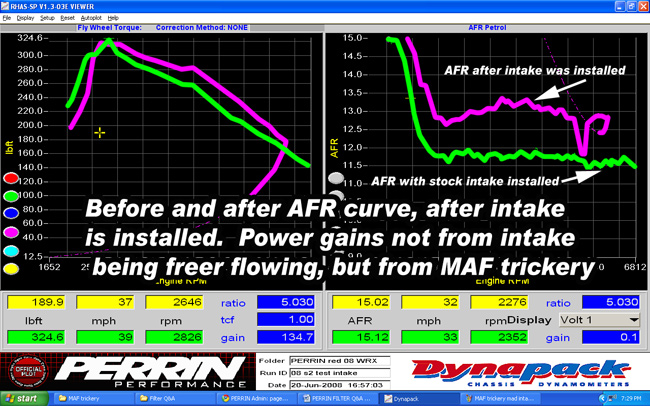

Many big intake system manufactures use this MAF trickery to add HP. Then claim its their wonderful filter making the HP, when it fact its not. An example of an intake system that doesn't effect the MAF signal is one found here.

This shows our intake system installed on an EVO 9. The before and after shows the Air Fuel Ratio being the same not to mention 30 more Wheel HP. This Intake makes HP the legit way by freeing up the intake side of the system, not by screwing with the MAF sensor.

This is an example of an intake system with a very picky MAF sensor and is one that requires an ECU retune in order to make the intake run the car properly.

In this example the intake leans out the AFR to the point of being dangerous. This does add power initially, but the lean mixture led to engine knock, and is why the run was not completed. You can see how in some cases the intake system weather it be a complete new system or a simple filter change, can make a huge difference in how it runs. This is just a small snipet of how and why filters can effect power. Look shortly for a much more indepth look at how and why intakes work.

HISTORY

The history of PERRIN filters started life back in 2002. Our first filter was a barrel shaped dual layer foam filter with inner and outer cage. We felt the outer cage looked kind of cool and gave it a look much different than other filters. But was a little heavy and later on we moved to a cone shaped filter version and hard top with no cage. This removing of the cage was a good step as it allow for much easier cleaning. This was a great benefit of our filter and we heavily played it up as a new feature. From there we changed to barrel shape and a couple logos later we came to the new two piece version. In all this time people didn't really take our weird foam filters and it might have been because of the color, which we took note of. The most recent change was to a black foam! This eliminates the issue had with the looks of the filter and makes for an innovative way to determine if the filter needs cleaning. The "white" logo is used a guide for cleaning intervals. And it makes it look really cool!

|

TRY AGAINFirst major design change moved away from a cylinder shape to a tapered cone. It fit better under the hood and looked a little less sterile |

|

CURRENT DESIGNBlack foam which looks cleaner as the filter loads with dirt. The white logo will actually start to fade as the filter collects with dirt helping the driver determine when to clean the filter. The new two piece design allows the user to remove the foam filter sock from the support cage for easy cleaning. Video of how to remove filter sleeve |

RECAP

- Foam filters filter better than any other filter.

- Foam filters hold significantly more dirt than any other filter.

- Foam can be washed and reused hundreds of times.

- Foam filter service interval is 2-3 times that of other filters.

- Reusable foam filters are environmentally friendly with little to no waste.

- Foam filters are free flowing, increasing the performance of your engine.

- Foam gives better fuel economy between service intervals.

- Priced only slightly higher than an OEM paper replacement.

BONUS MATERIAL

Here is an independent test done on the largest Mitsubishi EVO forum, EvolutionM.net. This test compares many popluar filters together, and all done on the same car on the same dyno, and same day! Again more proof the PERRIN Foam filter is the best. If your name is John Leitl or Adam Taft, the secret password is endlink and if you actually read this, you get a free lunch on me! This is only valid for one lunch!

Foam filter video from Trueflow filters. These guys are not affiliated with us but have gone the extra mile with this video to show you foam at work.

Below is a test done by someone in Nevada rating all the main types of filter using SAE approved methods.

Here's the info I have on air filter performance. Tests were done using SAE J726C Test Method 5-best --> 1-worst

| Oiled foam (AMSOIL,UNI) | Paper | Oil Bath | Oiled Gauze (K&N) | |

| Large particle efficiency | 5 | 5 | 5 | 4 |

| Small particle efficiency | 5 | 4 | 1 | 2 |

| Airflow capacity | 5 | 2 | 3 | 5 |

| Dust holding capacity | 4 | 2 | 5 | 2 |

| Load up characteristic | 4 | 1 | 5 | 1 |

| Backfire characteristic | 3 | 2 | 5 | 3 |

| Cleanability | 4 | 1 | 4 | 3 |

As you can see, K&Ns are great for airflow, which is what they were designed for. Their original application was on racing engines, where airflow is important and ultimate engine life was of little consern. They are not as good at filtering as paper or oiled foam types.

Ed Hackett [email protected] The Desert Research Institute

DoD #0200 WMTC BMWRA DIOC Reno, Nevada (702) 673-7380

KotLS KotLE DotD #0003

900SS K100RS 501 CAMEL